Nheyo dzekutanga dzePCB pad dhizaini

Zvinoenderana nekuongororwa kweiyo solder yakabatana chimiro cheakasiyana zvikamu, kuti isangane nekuvimbika zvinodiwa zvemasolder majoini, PCB pad dhizaini inofanirwa kugona zvinotevera zvakakosha zvinhu:

1, symmetry: migumo yese yepedhi inofanirwa kunge yakaenzana, kuitira kuti ive nechokwadi chekuyeresa kweyakanyungudutswa solder pamusoro tension.

2. Pad spacing: Iva nechokwadi chehukuru hwakakodzera hwemakumbo echikamu chekupedzisira kana pini uye padhi.Yakakurisa kana diki padhi spacing inokonzeresa kukanganisa kwewelding.

3. Kukura kwakasara kwepadhi: hukuru hwakasara hwechikamu chekupedzisira kana pini mushure mekuputika nepedhi inofanira kuva nechokwadi chokuti solder joint inogona kuumba meniscus.

4.Pad width: Inofanira kunge yakanyatsoenderana nehupamhi hwekupedzisira kana pini yechikamu.

Solderability matambudziko anokonzerwa nekuremara kwekugadzira

01. Ukuru hwepadhi hunosiyana

Saizi yedhizaini yedhizaini inoda kuenderana, kureba kunoda kuve kwakakodzera kune iyo siyana, iyo pad yekuwedzera kureba ine yakafanira renji, yakapfupika kana yakarebesa inotarisana nechiitiko che stele.Ukuru hwepadhi hahuenderani uye tension haina kuenzana.

02. Iyo hupamhi hwepadhi yakafara kupfuura pini yechigadzirwa

Pad dhizaini haigone kuve yakafara zvakanyanya kupfuura zvikamu, hupamhi hwepadhi i2mil yakafara kupfuura zvikamu.Yakanyanya kupamhama padhi hupamhi huchatungamira kune chikamu chinotamiswa, mhepo welding uye isina kukwana tini padhi uye mamwe matambudziko.

03. Pedhi upamhi hudiki pane pini yemudziyo

Iyo hupamhi hwepadhi dhizaini yakamanikana kupfuura hupamhi hwezvikamu, uye nzvimbo yekusangana kwepadhi nezvikamu zvishoma kana SMT patches, izvo zviri nyore kuita kuti zvikamu zvimire kana kutendeuka.

04. Kureba kwepadhi kwakareba kupfuura pini yechigadzirwa

Iyo pedhi yakagadzirwa haifaniri kunge yakareba kudarika pini yechikamu.Kupfuura imwe nhanho, yakawandisa flux kuyerera panguva yeSMT reflow welding inokonzeresa kuti chikamu chikweve chinzvimbo chekubvisa kune rimwe divi.

05. Kupatsanurana pakati pemapedhi ipfupi pane yezvikamu

Dambudziko repfupi-redunhu repad spacing rinowanzoitika muIC pad spacing, asi dhizaini yemukati yemamwe mapadhi haigone kupfupika kupfuura kupatsanurwa kwepini yezvikamu, izvo zvinokonzeresa kupfupika kana ikapfuura humwe huwandu hwehunhu.

06. Pini upamhi hwepadhi idiki zvakanyanya

Mune SMT chigamba chechikamu chimwe chete, kukanganisa mupadhi kuchaita kuti chikamu chibude kunze.Semuenzaniso, kana padhi iri diki zvakanyanya kana chikamu chepedhi chiri chidiki zvakanyanya, haizogadziri tin kana tini shoma, zvichikonzera kunetsana kwakasiyana kumativi ese.

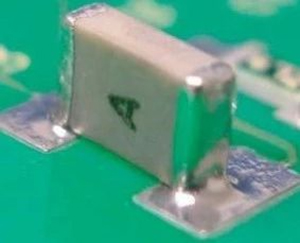

Mhosva chaidzo dzediki bias pads

Saizi yemapedhi emidziyo haienderane nehukuru hwePCB yekurongedza

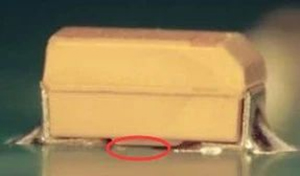

Tsanangudzo yedambudziko:Kana chimwe chigadzirwa chagadzirwa muSMT, inowanikwa kuti inductance inogadziriswa panguva yekumashure welding yekuongorora.Mushure mekusimbisa, inowanikwa kuti inductor zvinhu hazvienderane nemapads.* 1.6mm, zvinhu zvichadzoserwa shure mushure mekugadzira.

Impact:Kubatana kwemagetsi kwezvinhu kunova kwakashata, kunokanganisa kushanda kwechigadzirwa, uye zvakakomba zvinokonzera kuti chigadzirwa chisakwanise kutanga kazhinji;

Kuwedzera kwedambudziko:Kana iyo isingakwanisi kutengwa kuhukuru hwakafanana nePCB pad, sensor uye kushorwa kwemazuva ano kunogona kusangana nezvinhu zvinodiwa nedunhu, ipapo njodzi yekuchinja bhodhi.

Nguva yekutumira: Kubvumbi-17-2023