Ongororo yakadzama yeSMT chigamba uye THT kuburikidza negomba plug-in PCBA matatu anti pendi coating process uye akakosha matekinoroji!

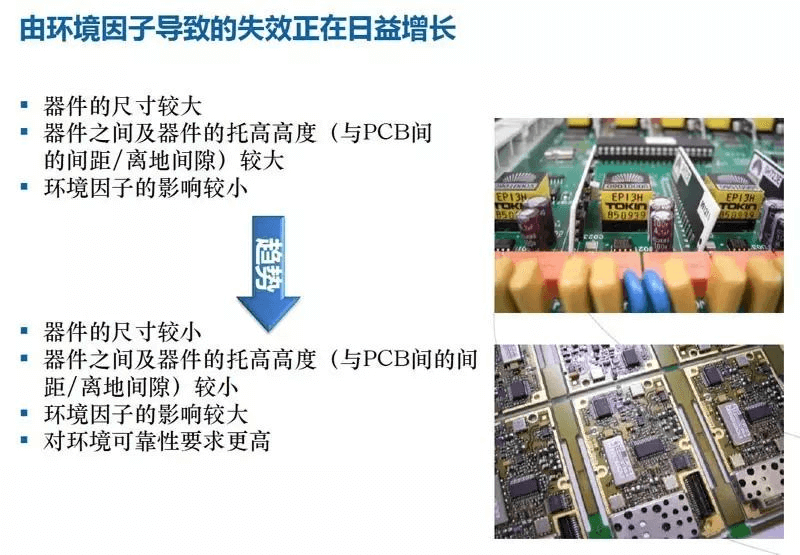

Sezvo saizi yePCBA zvikamu zvidiki uye zvidiki, density inova yakakwirira uye yakakwirira;Iyo inotsigira kureba pakati pezvishandiso nemidziyo (iyo nzvimbo pakati pePCB uye yepasi clearance) iri kuramba ichidzika uye idiki, uye pesvedzero yezvakatipoteredza zvinhu paPCBA iri kuwedzerawo.Naizvozvo, tinoisa pamberi pepamusoro zvinodiwa pakuvimbika kwePCBA yezvigadzirwa zvemagetsi.

1.Environmental factors uye maitiro avo

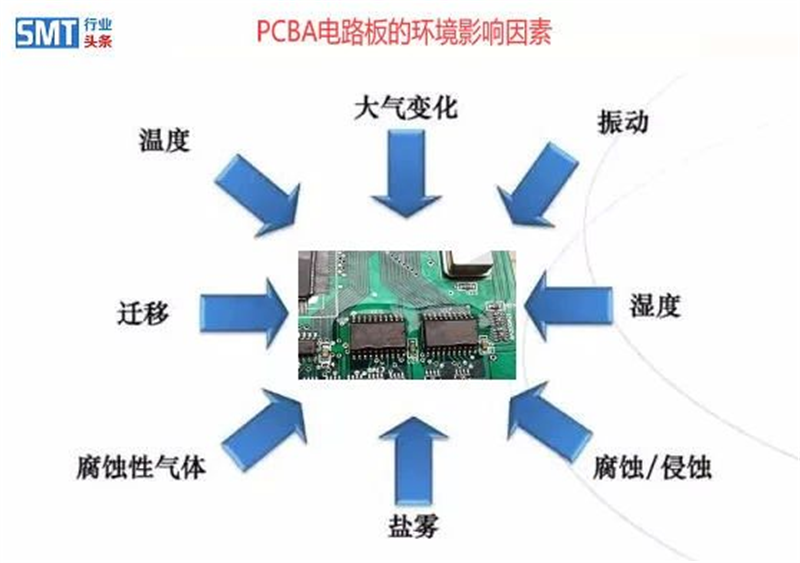

Zvakajairwa zvakatipoteredza zvinhu zvakaita sehunyoro, guruva, munyu pfapfaidzo, mold, nezvimwe, zvinogona kukonzera akasiyana kutadza matambudziko ePCBA.

Humidity

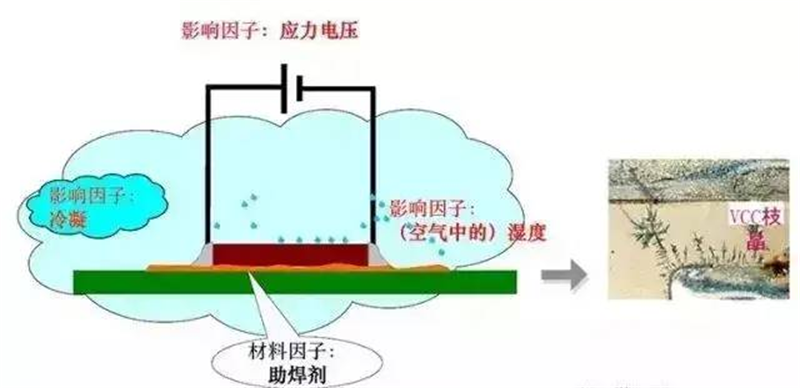

Zvinenge zvese zvemagetsi PCB zvikamu zviri mumhepo yekunze zviri panjodzi yekuora, pakati peiyo mvura ndiyo inonyanya kukosha svikiro rekuora.Mamorekuru emvura madiki zvekupinda mukati memesh molecular gap yezvimwe zvinhu zvepolymer uye kupinda mukati kana kusvika kune simbi yepasi kuburikidza nepini yejasi kuita ngura.Kana mhepo yasvika kune imwe humidity, inogona kukonzera PCB electrochemical migration, kuvuza ikozvino uye kukanganiswa kwechiratidzo mumatunhu akakwirira.

Mhepo / mwando + ionic zvinosvibisa (munyu, flux inoshanda vamiririri) = conductive electrolytes + stress voltage = electrochemical migration

Apo iyo RH mumhepo inosvika 80%, pachava nefirimu remvura rine hutema hwe5 ~ 20 molecules, uye marudzi ose emamorekuru anogona kufamba akasununguka.Kana kabhoni iripo, electrochemical reactions inogona kuitika.

Apo RH inosvika 60%, iyo yepamusoro yezvigadzirwa ichaita 2 ~ 4 mamorekuru emvura gobvu remvura firimu, kana pane zvinosvibisa zvinonyunguduka mukati, pachava nemakemikari anoita;

Kana RH <20% mumhepo, dzinenge dzese corrosion phenomena dzinomira.

Naizvozvo, hunyoro-uchapupu chikamu chakakosha chekuchengetedzwa kwechigadzirwa.

Pamidziyo yemagetsi, hunyoro hunouya nenzira nhatu: mvura, condensation uye mhute yemvura.Mvura ielectrolyte inonyungudutsa maion anoparadza akawanda anoparadza simbi.Kana tembiricha yeimwe chikamu chemidziyo iri pazasi pe "dova point" (tembiricha), pachava nekudzikama pamusoro pepamusoro: zvimiro zvikamu kana PCBA.

Guruva

Kune guruva mumhepo, guruva adsorbed ion zvinosvibisa zvinogara mukati memidziyo yemagetsi uye zvinokonzera kukundikana.Iri idambudziko rakajairika nekutadza kwemagetsi mumunda.

Guruva rakakamurwa kuita marudzi maviri: guruva rakakora ndiro dhayamita ye2.5 ~ 15 microns yezvisina kujairika zvimedu, kazhinji hazvizokonzeresa kukanganisa, arc uye mamwe matambudziko, asi zvinokanganisa yekubatanidza yekubatanidza;Hupfu hwakatsetseka zvidimbu zvisingaenzaniswi zvine dhayamita isingasviki 2.5 microns.Guruva rakanaka rine kumwe kunamatira paPCBA (veneer), iyo inogona kubviswa chete ne-anti-static brush.

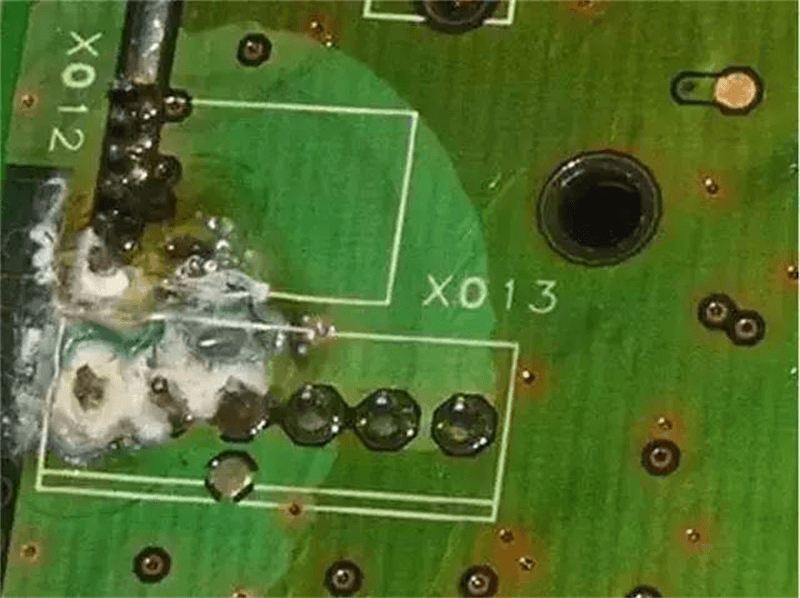

Njodzi dzeguruva: a.Nekuda kweguruva rinogadzika pamusoro pePCBA, electrochemical corrosion inogadzirwa, uye chiyero chekutadza chinowedzera;b.Guruva + kunyorova kupisa + mhute yemunyu yakakonzera kukuvadzwa kukuru kwePCBA, uye kukundikana kwemidziyo yemagetsi ndiyo yaive yakanyanya muindasitiri yemakemikari nenzvimbo yemigodhi padyo nemahombekombe, gwenga (nyika ine saline-alkali) uye kumaodzanyemba kweRwizi Huaihe panguva yekuvhuvhu uye. mwaka wemvura.

Nokudaro, kudzivirira guruva chikamu chinokosha chechigadzirwa.

Kupfapfaidza munyu

Kugadzirwa kwemunyu spray:Kupfapfaidza munyu kunokonzerwa nezvinhu zvakasikwa zvakadai semafungu egungwa, masaisai, kutenderera kwemhepo (monsoon) pressure, kupenya kwezuva zvichingodaro.Ichakukurwa ichienda mukati menyika nemhepo, uye kudzika kwayo kuchadzikira nechinhambwe kubva kumahombekombe.Kazhinji, kuwanda kwemunyu wekupfapfaidza i1% yemhenderekedzo yegungwa kana iri 1Km kubva kumahombekombe (asi inozofuridzira kure munguva yechamupupuri).

Kukuvadza kwesalt spray:a.kukanganisa kuvharwa kwezvikamu zvesimbi;b.Kuwedzera kwe electrochemical corrosion speed kunotungamirira kukuputsika kwetambo dzesimbi uye kukundikana kwezvikamu.

Zvakafanana zvinokonzeresa corrosion:a.Dikita reruoko rine munyu, urea, lactic acid uye mamwe makemikari, ane zvakafanana corrosive mhedzisiro pamidziyo yemagetsi semunyu wekupfapfaidza.Nokudaro, magirovhosi anofanira kupfekwa panguva yegungano kana kushandiswa, uye kupfeka hakufaniri kubatwa nemaoko asina;b.Kune ma halogens uye maasidhi mumhepo inoyerera, iyo inofanirwa kucheneswa uye yavo yakasara yekuisa inodzorwa.

Naizvozvo, kudzivirira kupfapfaidza munyu chikamu chakakosha chekuchengetedzwa kwezvigadzirwa.

Mold

Mildew, zita rinowanzozivikanwa refilamentous fungi, zvinoreva "fungus moldy," inowanzoita mycelium yakasvibira, asi haiburitse miviri mikuru inobereka sehowa.Munzvimbo dzakanyorova uye dzinodziya, zvinhu zvakawanda zvinokura paziso rakashama zvimwe zvemakororo asina kujeka, akatsetseka kana kuti cobweb, inova mold.

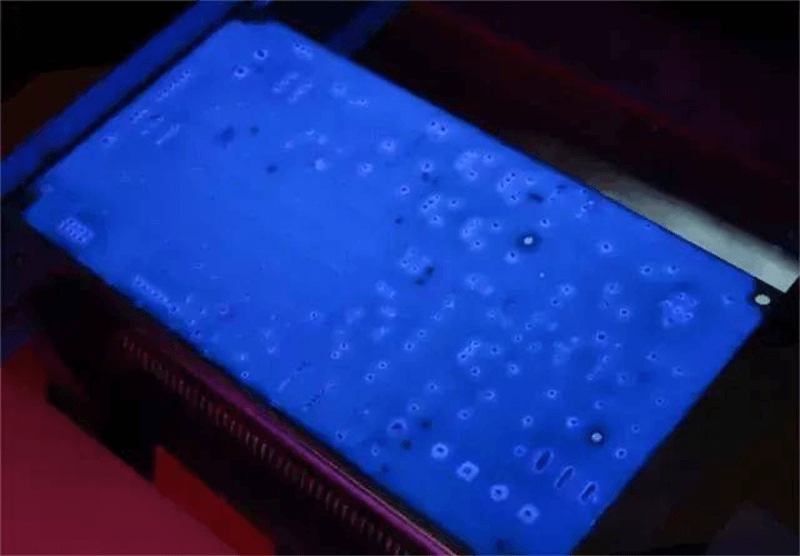

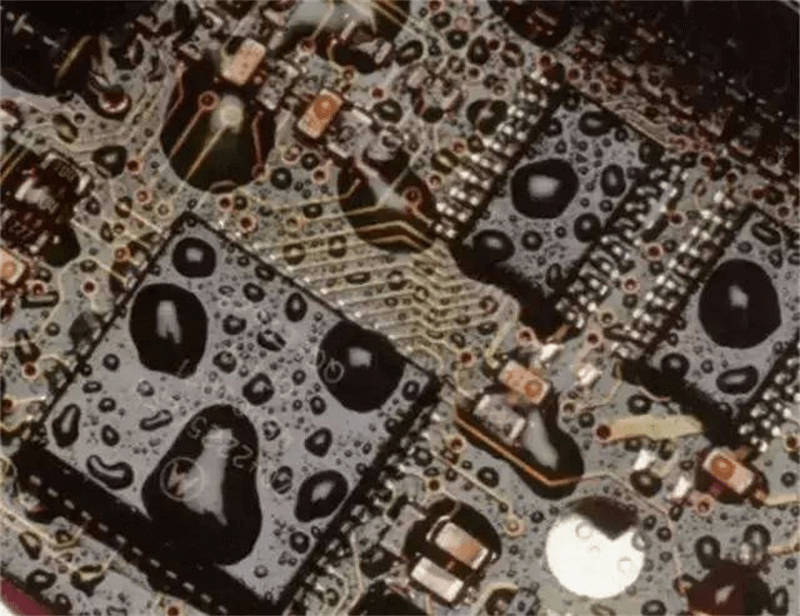

FIG.5: PCB mildew chiitiko

Kukuvadza kwe mold: a.mold phagocytosis uye kupararira kunoita kuti kuvharwa kwezvinhu zvipenyu kuderera, kukuvadzwa uye kukundikana;b.Iyo metabolites ye mold ndeye organic acids, iyo inokanganisa kusungirirwa uye simba remagetsi uye inoburitsa magetsi arc.

Naizvozvo, anti-mold chikamu chakakosha chezvigadzirwa zvekudzivirira.

Tichifunga nezvezvinhu zviri pamusoro apa, kuvimbika kwechigadzirwa kunofanirwa kuve kwakavimbiswa zviri nani, kunofanirwa kuve kwakaparadzaniswa nekunze kwekunze zvakaderera sezvinobvira, saka maitiro ekuputira chimiro anounzwa.

Kupfekedza PCB mushure mekupfekedza maitiro, pasi pemwenje wepepuru wekupfura mhedzisiro, iyo yepakutanga yekupfekedza inogona kuve yakanaka kwazvo!

Matatu anti-pendi coatingzvinoreva kupfekedza chitubu chakatetepa chinodzivirira pamusoro pePCB.Ndiyo inonyanya kushandiswa post-welding coating method parizvino, dzimwe nguva inonzi surface coating uye conformal coating (zita rechirungu: coating, conformal coating).Ichaparadzanisa zvinhu zvemagetsi zvinonzwisisika kubva munzvimbo ine hutsinye, inogona kuvandudza zvakanyanya kuchengetedzeka uye kuvimbika kwezvigadzirwa zvemagetsi uye kuwedzera hupenyu hwebasa rezvigadzirwa.Matatu ekudzivirira-pendi coating anogona kuchengetedza dunhu / zvikamu kubva kune zvakatipoteredza zvinhu zvakaita sehunyoro, zvinosvibisa, ngura, kushushikana, kuvhunduka, mechanical vibration uye kutenderera kwekupisa, uku uchivandudza simba remakanika uye hunhu hwekudzivirira kwechigadzirwa.

Mushure mekuputira maitiro ePCB, gadzira firimu rekudzivirira rakajeka pamusoro, rinogona kudzivirira kupindira kwemvura nekunyorova, kudzivirira kubuda uye kupfupika kwedunhu.

2. Pfungwa huru dzekuputira nzira

Zvinoenderana nezvinodiwa zveIPC-A-610E(Electronic Assembly Testing Standard), inonyanya kuratidzwa mune zvinotevera zvinhu:

Dunhu

1. Nzvimbo dzisingagone kuvharwa:

Nzvimbo dzinoda kubatanidza magetsi, dzakaita semapadhi egoridhe, zvigunwe zvegoridhe, simbi nemumaburi, maburi ebvunzo;

Mabhatiri uye zvigadziriso zvebhatiri;

Connector;

fuse uye casing;

Chigadzirwa chekupisa kupisa;

Jumper wire;

Lenzi yechinhu che optical;

Potentiometer;

Sensor;

Hapana switch yakavharwa;

Dzimwe nzvimbo uko kupfeka kunogona kukanganisa kushanda kana kushanda.

2. Nzvimbo dzinofanirwa kuvharwa: majoini ese ekutengesa, mapini, zvikamu uye conductors.

3. Nzvimbo dzekusarudza

Ukobvu

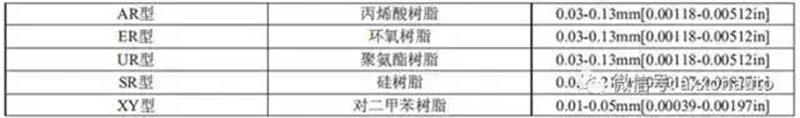

Ukobvu hunopimwa pahwaro hwakati sandara, husingadziviriri, hwakaporeswa hwechikamu chedunhu rakadhindwa kana pandiro yakanamirwa inoenda nechikamu chacho.Mabhodhi akabatanidzwa anogona kunge ari emhando imwechete semapuranga akadhindwa kana zvimwe zvisiri-porous, sesimbi kana girazi.Wet film gobvu kuyerwa kunogona kushandiswawo senzira yekusarudza yekupfekedza ukobvu kuyerwa, chero paine hukama hwekushandura hwakanyorwa pakati pekunyorova nekuoma kwefirimu ukobvu.

Tafura 1: Hukobvu renji chiyero kune yega yega yemhando yekupfekedza zvinhu

Test nzira ukobvu:

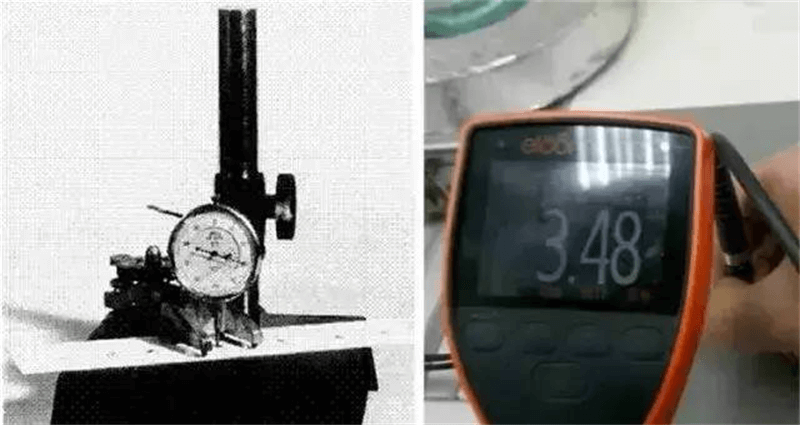

1. Dry firimu ukobvu kuyera chishandiso: micrometer (IPC-CC-830B);b Dry Firimu ukobvu tester (simbi base)

Mufananidzo 9. Micrometer yakaoma firimu zvishandiso

2. Kuyera firimu kuyera kuyerwa: kukora kwefirimu rakanyorova rinogona kuwanikwa nekunyorova kwefirimu ukobvu hwekuyera chiridzwa, uyezve kuverengerwa nechikamu cheglue solid content.

Ukobvu hwefirimu yakaoma

MuFIG.10, iyo yakanyorova yefirimu ukobvu yakawanikwa neyakanyorova firimu ukobvu tester, uye ipapo iyo yakaoma firimu ukobvu kwakaverengerwa.

Edge resolution

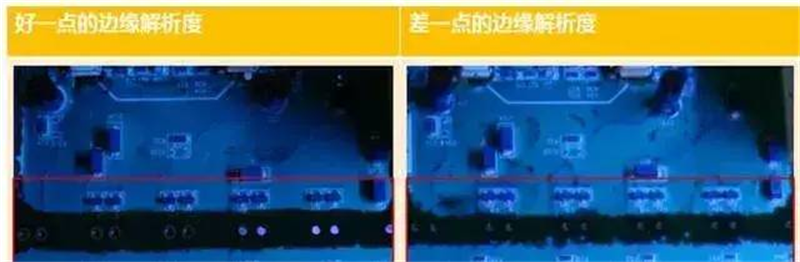

Tsanangudzo: Mumamiriro ezvinhu akajairika, spray valve spray kunze kwemutsetse wemutsara haizove yakanyatsojeka, pachagara paine imwe burr.Isu tinotsanangura hupamhi hweburr sechigadziriso chemupendero.Sezvinoratidzwa pazasi, saizi ye d kukosha kwekugadziriswa kwemupendero.

Ongorora: Kugadziriswa kwemupendero ndiko kudiki kuri nani, asi zvakasiyana zvinodiwa nevatengi hazvina kufanana, saka iyo chaiyo yakavharwa kumucheto resolution sekurebesa kuzadzisa zvinodiwa nevatengi.

Mufananidzo 11: Edge resolution kuenzanisa

Uniformity

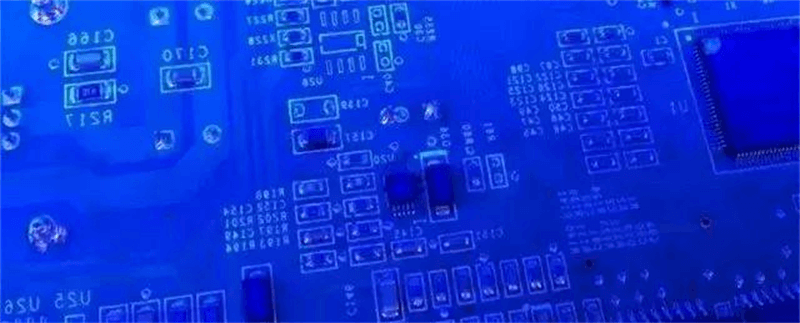

Glue inofanira kunge yakaita sehupamhi hweyunifomu uye firimu yakatsetseka uye yakajeka yakavharwa muchigadzirwa, kusimbiswa kuri pakufanana kweglue yakavharwa muchigadzirwa chiri pamusoro penzvimbo, saka, inofanira kunge yakafanana nehupamhi, hapana matambudziko ekugadzirisa: kuputika, stratification, mitsetse yeorenji, kusvibiswa, capillary phenomenon, mabhuru.

Mufananidzo 12: Axial otomatiki AC akateedzera otomatiki coating muchina coating maitiro, kufanana kunoenderana zvakanyanya

3. Kuzadzikiswa kwekugadzira nzira

Coating process

1 Gadzirira

Gadzirira zvigadzirwa uye glue nezvimwe zvinhu zvinodiwa;

Sarudza nzvimbo yekuchengetedzwa kwenzvimbo;

Sarudza ruzivo rwakakosha rwekuita

2: Geza

Inofanira kucheneswa munguva pfupi mushure mekuputika, kudzivirira tsvina yekutsvaira yakaoma kuchenesa;

Sarudza kana chikuru chinosvibisa chiri polar, kana kuti kwete-polar, kuitira kuti usarudze mumiririri akakodzera wekuchenesa;

Kana doro rekuchenesa dhizha rinoshandiswa, nyaya dzekuchengetedza dzinofanira kubhadharwa kune: panofanira kuva nemhepo yakanaka uye kutonhora uye kuomeswa kwemitemo mushure mekugeza, kudzivirira kusara kwekunyungudika kwemhepo kunokonzerwa nekuputika muchoto;

Mvura yekuchenesa, ine alkaline yekuchenesa mvura (emulsion) kushambidza kubuda, uye wozosuka nemvura yakachena kuchenesa mvura yekuchenesa, kusangana nemitemo yekuchenesa;

3. Masking kudzivirira (kana pasina midziyo yekuvhara yakasarudzwa inoshandiswa), kureva, mask;

Inofanira kusarudza isina-adhesive firimu haizotamisi tepi yepepa;

Anti-static bepa tepi inofanira kushandiswa kudzivirira IC;

Zvinoenderana nezvinodiwa zvekudhirowa kune mamwe maturusi ekudzivirira kudzivirira;

4. Dehumidify

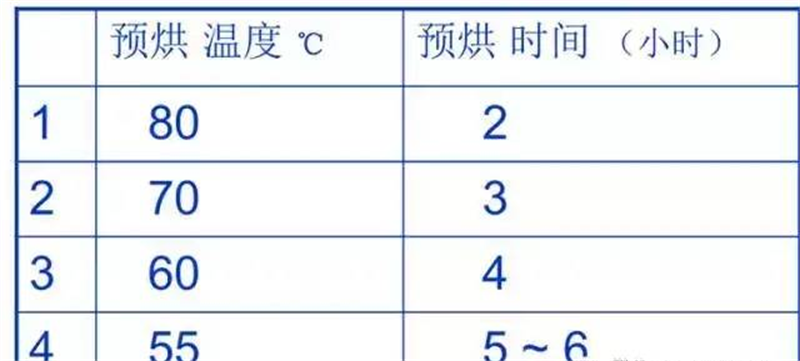

Mushure mekuchenesa, iyo yakadzivirirwa PCBA (chikamu) inofanira kunge isati yaomeswa uye yakasvibiswa isati yavhara;

Sarudza tembiricha / nguva pre-kuomesa maererano tembiricha inobvumirwa nePCBA (chikamu);

PCBA (chikamu) inogona kubvumidzwa kuona tembiricha / nguva yepre-drying table

5 Coat

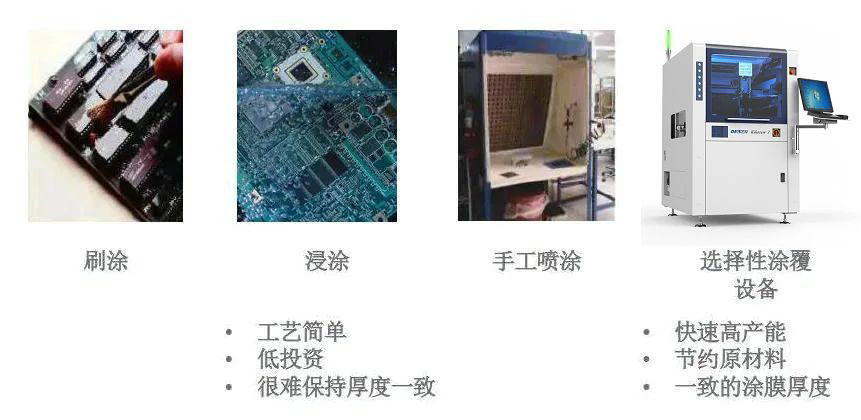

Maitiro ekuputira chimiro anoenderana nePCBA kuchengetedza zvinodiwa, iripo process midziyo uye iripo tekinoroji reserve, iyo inowanzoitwa nenzira dzinotevera:

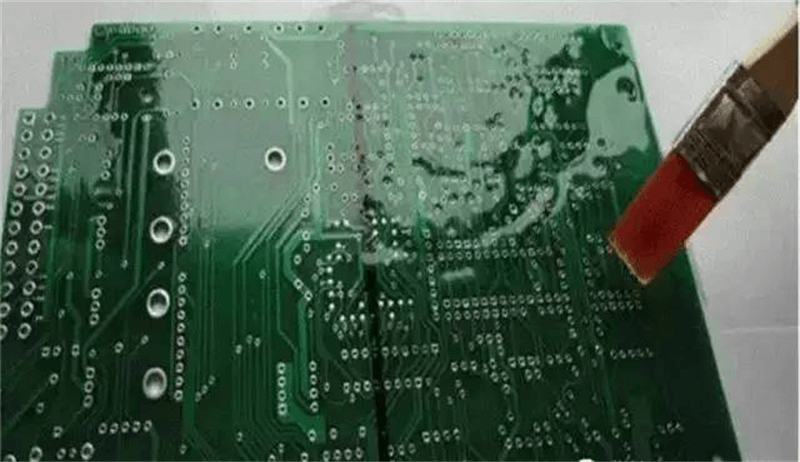

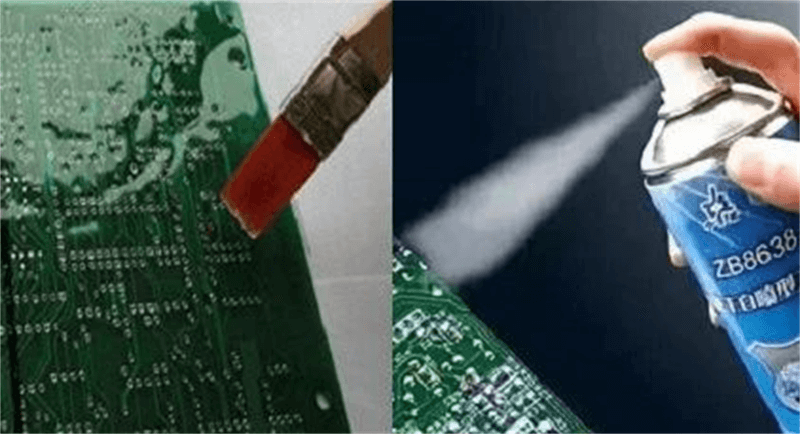

a.Geza neruoko

Mufananidzo 13: Nzira yekukwesha maoko

Brush coating ndiyo inonyanya kushanda maitiro, akakodzera diki batch kugadzirwa, PCBA chimiro chakaomesesa uye chakaomeswa, inoda kuchengetedza zvinodiwa zvekudzivirira zvehasha zvigadzirwa.Nokuti kuputika kwebrashi kunogona kudzorwa zvakasununguka, kuitira kuti zvikamu zvisingabvumirwi kupenda hazvizosvibiswa;

Brush coating inopedza zvinhu zvishoma, zvakakodzera pamutengo wepamusoro wependi yezvikamu zviviri;

Nzira yekupenda ine zvinodiwa zvakanyanya pamushandisi.Kusati kwavakwa, madhirowa uye zvinodikanwa zvekupfekedza zvinofanirwa kunyatsogayiwa, mazita ezvikamu zvePCBA anofanirwa kuzivikanwa, uye zvikamu zvisingabvumirwe kuvharwa zvinofanirwa kunyorwa nezviratidzo zvinobata maziso;

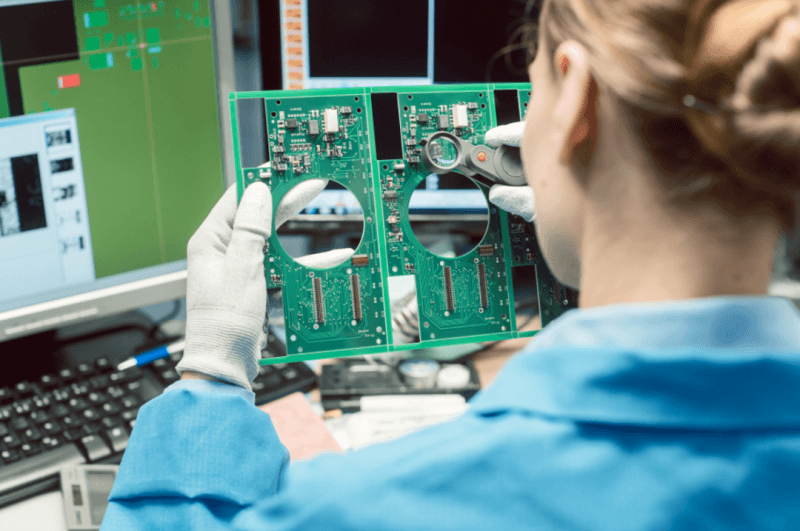

Vashandi havabvumirwi kubata iyo yakadhindwa plug-in nemaoko avo chero nguva kudzivirira kusvibiswa;

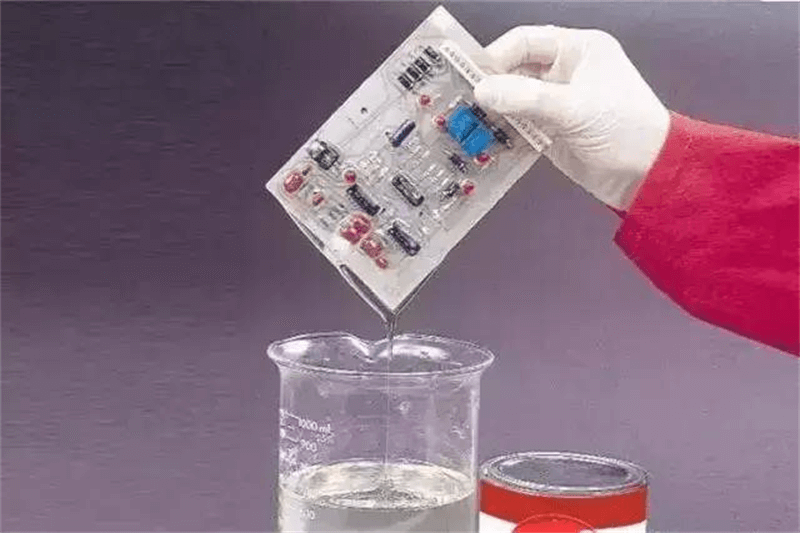

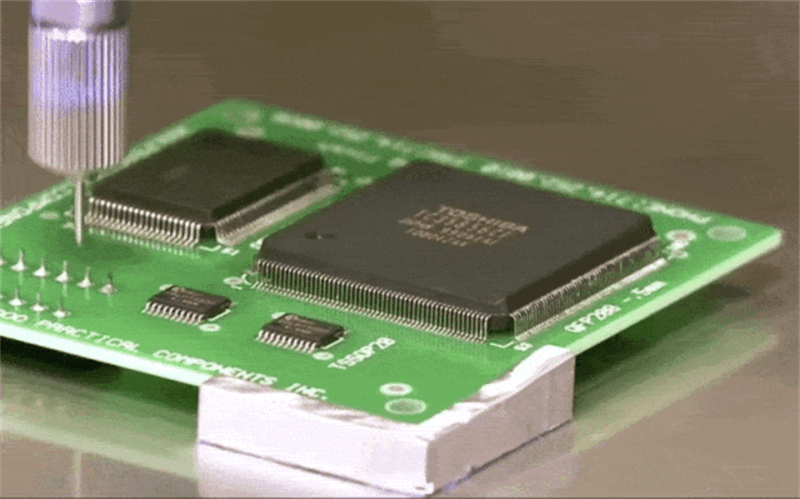

b.Dip neruoko

Mufananidzo 14: Nzira yekuputira nemaoko

Iyo dip coating process inopa yakanakisa coating mhedzisiro.Yunifomu, inoenderera yakavhara inogona kuiswa kune chero chikamu chePCBA.Iyo dip coating process haina kukodzera maPCbas ane anochinjika capacitor, yakanaka-tuning magineti cores, potentiometers, cup-yakaita magineti cores uye zvimwe zvikamu zvine kusaina chisimbiso.

Zvikamu zvakakosha zve dip coating process:

Gadzirisa viscosity yakakodzera;

Dzora kumhanya uko PCBA inosimudzwa kudzivirira mabhuru kubva pakuumbwa.Kazhinji hapana kupfuura 1 mita pasekondi;

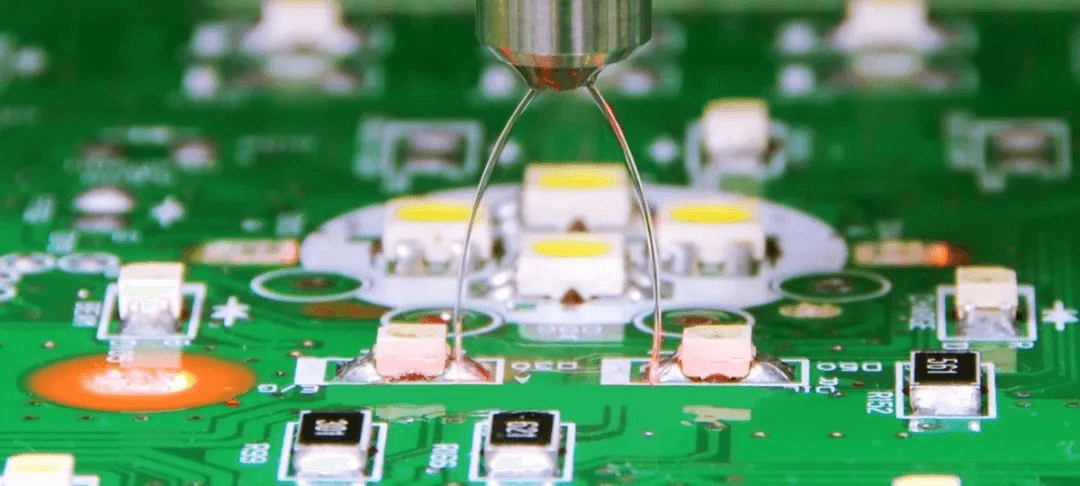

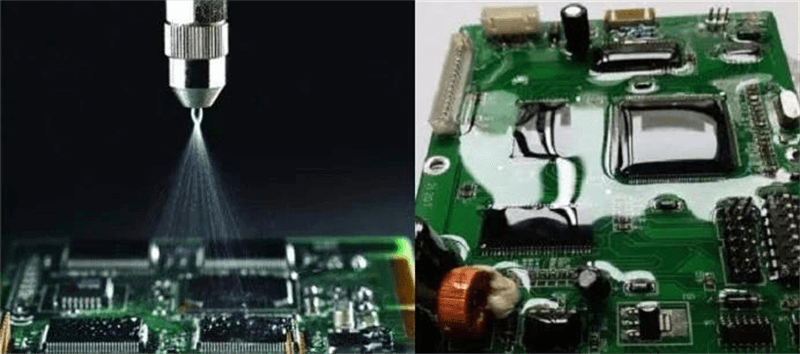

c.Kupfapfaidza

Kupfapfaidza ndiyo inonyanya kushandiswa, iri nyore kubvuma nzira yekugadzira, yakakamurwa muzvikamu zviviri zvinotevera:

① Kupfapfaidza nemaoko

Mufananidzo 15: Kupfapfaidza nemaoko

Inokodzera iyo workpiece yakanyanya kuoma, yakaoma kuvimba neotomatiki midziyo yakawanda yekugadzira mamiriro, zvakare akakodzera kune chigadzirwa mutsetse siyana asi mashoma mamiriro, anogona kupfapfaidzwa kune imwe yakakosha chinzvimbo.

Cherechedzo kune kupfapfaidza kwemanyorero: mhute yependi inosvibisa mamwe maturusi, akadai sePCB plug-in, IC socket, mamwe anobatika anobatika uye mamwe mativi epasi, zvikamu izvi zvinoda kutarisisa kuvimbika kwedziviriro yekugara.Imwe pfungwa ndeyekuti mushandisi haafanire kubata plug yakadhindwa neruoko rwake chero nguva kudzivirira kusvibiswa kweplug yekubata kumeso.

② Kupfapfaidza otomatiki

Zvinowanzoreva kupfapfaidza otomatiki nemidziyo yekuisa yakasarudzika.Inokodzera kugadzirwa kwemazhinji, kuenderana kwakanaka, kurongeka kwepamusoro, kusvibiswa kwezvakatipoteredza kushoma.Nekuvandudzwa kweindasitiri, kuwedzera kwemutengo wevashandi uye zvakaomesesa zvinodiwa zvekuchengetedza kwezvakatipoteredza, otomatiki yekupfapfaidza michina iri kutsiva zvishoma nezvishoma dzimwe nzira dzekuputira.

Nekuwedzera kuri kuita otomatiki zvinodiwa zveindasitiri 4.0, tarisiro yeindastiri yachinja kubva pakupa michina yekupfekedza yakakodzera kugadzirisa dambudziko rekuita kwese kupfekedza.Automatic selective coating muchina - kupfekedza kwakaringana uye pasina kutambisa zvinhu, kwakakodzera kuwanda kwekuvhara, yakanyanya kukodzera kuwanda kweatatu anti-pendi coating.

Kuenzanisa kweautomatic coating machineuyetsika yekupfekedza maitiro

Traditional PCBA matatu-uchapupu pendi coating:

1) Brush coating: kune mabhubhu, masaisai, kubvisa bvudzi rebhurashi;

2) Kunyora: kunonoka, kurongeka hakugone kudzorwa;

3) Kunyura chidimbu chose: pendi yakashata, inononoka kumhanya;

4) Pfaya pfuti kupfapfaidza: kugadzirisa kuchengetedza, kukukurwa zvakanyanya

Coating machine coating:

1) Huwandu hwekupenda kwekupfapfaidza, nzvimbo yekupenda yekupfapfaidza uye nzvimbo yakarongedzwa nemazvo, uye hapana chikonzero chekuwedzera vanhu kupukuta bhodhi mushure mekupfapfaidza pendi.

2) Zvimwe zvikamu zveplug-in zvine nzvimbo yakakura kubva kumucheto kweplate inogona kupendwa zvakananga pasina kuisa chigadziriso, kuchengetedza vashandi vekuisa ndiro.

3) Hapana gasi volatilization, kuve nechokwadi chekushanda kwakachena nharaunda.

4) Yese substrate haidi kushandisa zvigadziriso kuvhara kabhoni firimu, kubvisa mukana wekudhumhana.

5) Matatu e-anti-pendi yekuputira ukobvu yunifomu, inovandudza zvakanyanya kugadzirwa uye kunaka kwechigadzirwa, asi zvakare dzivirira tsvina yependi.

PCBA otomatiki matatu anti pendi yekuputira muchina, yakanyatsogadzirirwa kupfapfaidza matatu anti pendi yakangwara yekupfapfaidza michina.Nekuda kwekuti zvinhu zvichapfapfaidzwa uye mvura yekupfapfaidza inoshandiswa zvakasiyana, muchina wekuputira mukuvaka kwechigadzirwa chechikamu chekusarudza wakasiyanawo, matatu anti-pendi yekuputira muchina unotora yazvino chirongwa chekudzora komputa, inogona kuona matatu-axis yekubatanidza, panguva imwechete yakashongedzerwa nekamera yekumisikidza uye yekutevera system, inogona kunyatso kudzora nzvimbo yekupfapfaidza.

Katatu anti-pendi yekupotera muchina, unozivikanwawo sematatu anti-pendi glue muchina, matatu anti-pendi yekupfapfaidza glue muchina, matatu anti-pendi mafuta ekupfapfaidza muchina, matatu anti-pendi yekupfapfaidza muchina, anonyanya kudzora mvura, pamusoro pePCB. yakafukidzwa nejira rematatu anti-pendi, senge impregnation, kupfapfaidza kana spin coating nzira paPCB pamusoro yakafukidzwa nejira rephotoresist.

Maitiro ekugadzirisa nguva nyowani yevatatu anti pendi coating kudiwa, rave dambudziko rekukurumidza kugadziriswa muindasitiri.Iyo otomatiki yekupfekedza michina inomiririrwa nechaiyo yakasarudzika yekupfekedza muchina inounza nzira nyowani yekushanda,kupfekedza kwakaringana uye pasina kutambisa zvinhu, iyo yakanyanya kukodzera nhamba yakakura yeatatu anti-pendi coating.