SMT welding zvikonzero

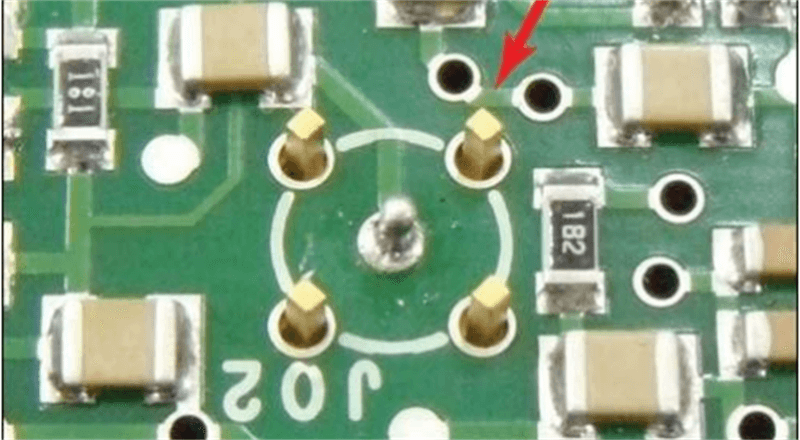

1. PCB pad design kukanganisa

Mukugadzira muitiro weimwe PCB, nekuti nzvimbo yacho idiki, gomba rinogona kungoridzwa padhi, asi solder paste ine fluidity, iyo inogona kupinda mugomba, zvichikonzera kusavapo kweiyo solder paste mu reflow welding, saka kana pini isingakwanire kudya tini, inotungamira kune yakadhirowa welding.

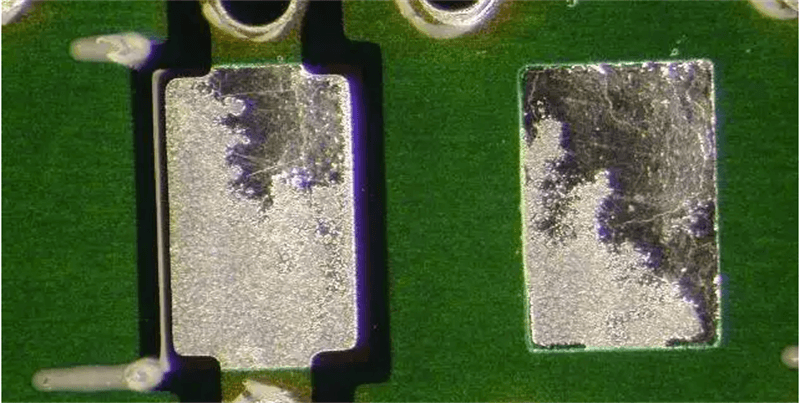

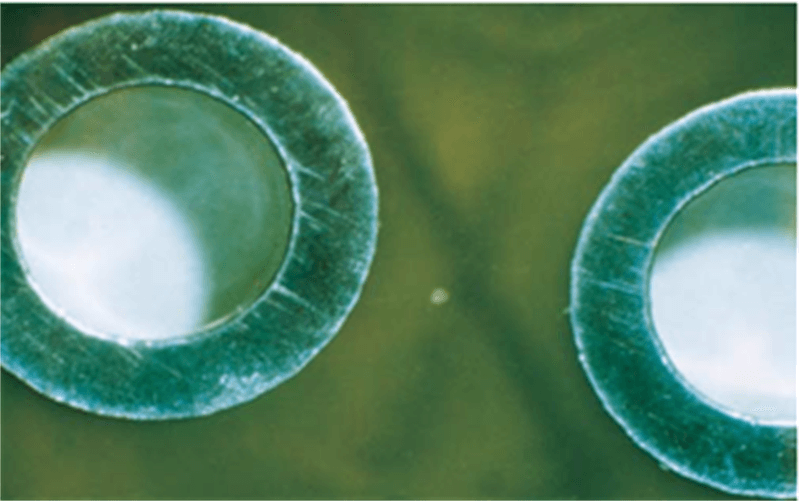

2.Pad surface oxidation

Mushure mekugadzirisazve pedhi ye oxidized, reflow welding inotungamira kune chaiyo welding, saka kana iyo pad yazara, inoda kuomeswa kutanga. Kana iyo oxidation yakakomba, inoda kusiiwa.

3.Reflow tembiricha kana yakakwirira tembiricha zone nguva haina kukwana

Mushure mekunge chigamba chapedzwa, tembiricha haina kukwana kana uchipfuura nepakati reflow preheating zone uye inogara tembiricha zone, zvichikonzera kumwe kupisa kunonyunguduka kukwira tini kusati kwaitika mushure mekupinda munzvimbo yekushisa kwekushisa kwepamusoro, zvichikonzera kusakwana kudya kwepini yepini, zvichiita kuti pave nehutachiwana.

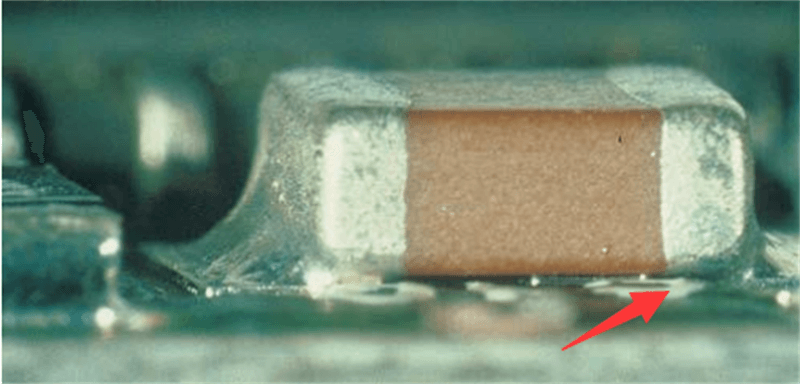

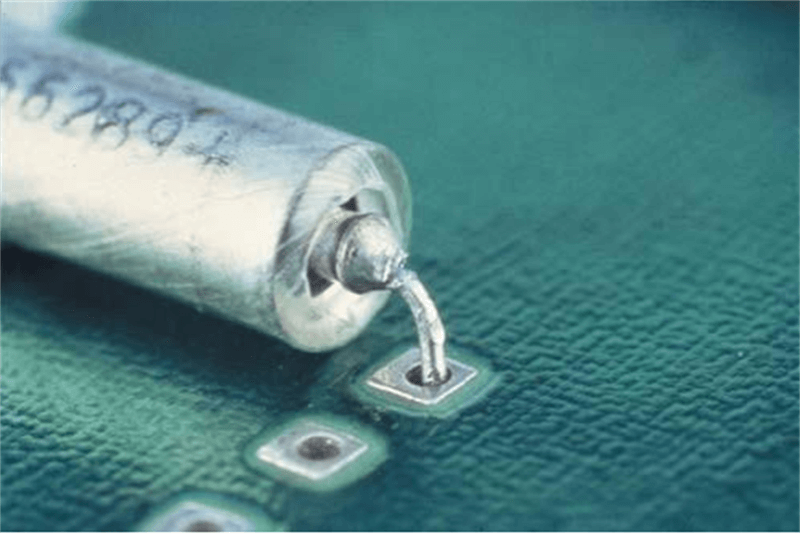

4.Solder paste kudhinda kushoma

Kana iyo solder paste ichikweshwa, inogona kunge iri nekuda kwekuvhurika kudiki mumambure esimbi uye kudzvinyirira kwakanyanya kweiyo printing scraper, zvichikonzera kushoma solder paste kudhinda uye kukurumidza kuvhurika kweiyo solder paste ye reflow welding, zvichikonzera kudhinda chaiko.

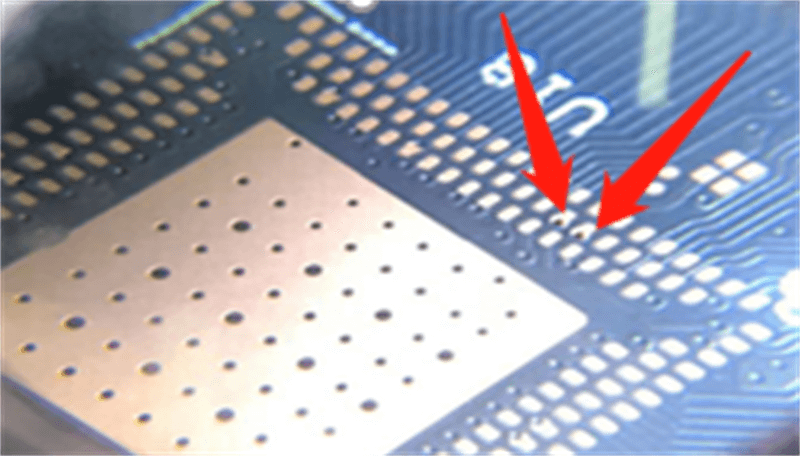

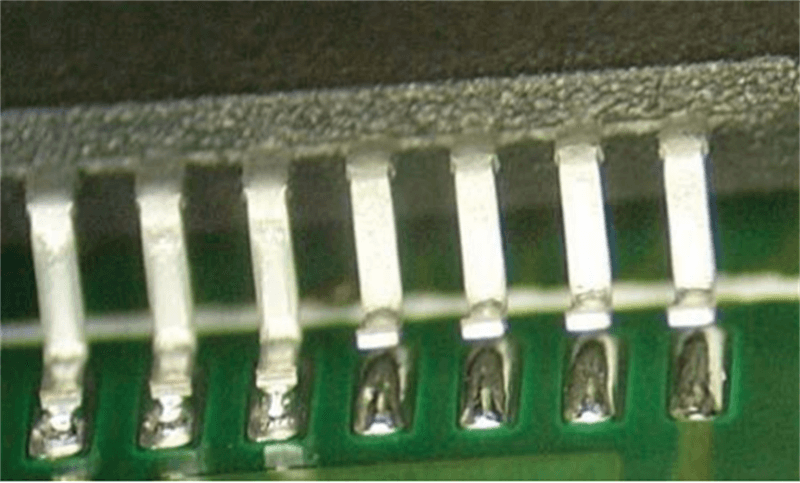

5.High-pini zvishandiso

Kana iyo yepamusoro-pini mudziyo uri SMT, zvingave kuti nekuda kwechimwe chikonzero, chikamu chacho chakaremara, PCB board yakakotama, kana kudzvanywa kwakashata kwemuchina wekuisa haina kukwana, zvichikonzera kunyungudika kwakasiyana-siyana kweiyo solder, zvichikonzera kusungirirwa chaiko.

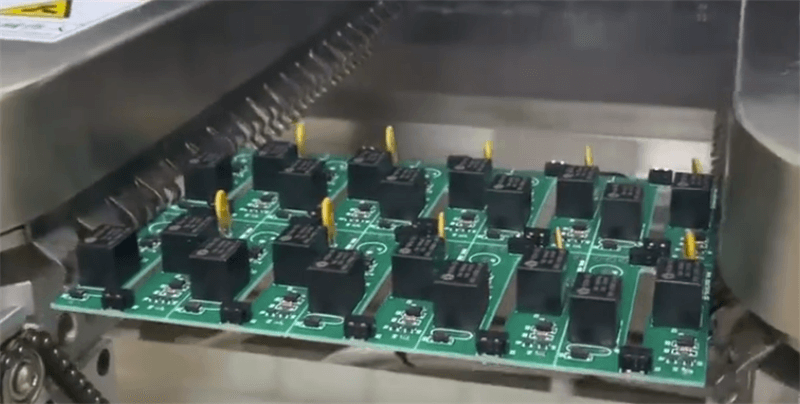

DIP chaiyo welding zvikonzero

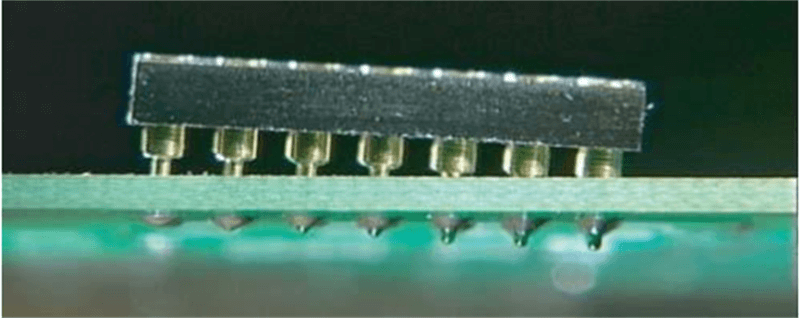

1.PCB plug-in mugomba kugadzira kuremara

PCB plug-in gomba, kushivirira kuri pakati pe ± 0.075mm, PCB yekurongedza gomba yakakura kupfuura pini yechishandiso chemuviri, mudziyo uchave wakasununguka, zvichikonzera kusakwana kwetin, virtual welding kana air welding uye mamwe matambudziko emhando.

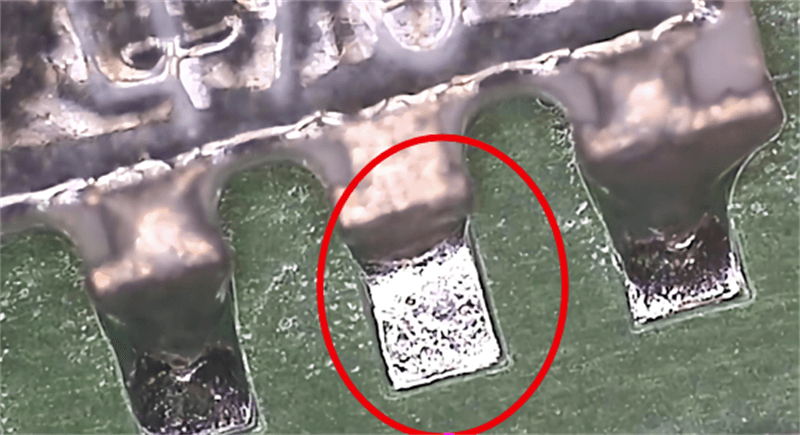

2.Pad uye gomba oxidation

PCB pad maburi haana kuchena, oxidized, kana kusvibiswa nezvinhu zvakabiwa, girisi, dikita stains, nezvimwewo, izvo zvinozotungamira mukusagadzikana weldability kana kusave-weldability, zvichikonzeresa kune chaiwo welding uye welding yemhepo.

3.PCB bhodhi uye mudziyo unhu zvinhu

Yakatengwa PCB mabhodhi, zvikamu uye zvimwe solderability hazvikodzeri, hapana bvunzo yekugamuchirwa yakasimba yakaitwa, uye kune matambudziko emhando akadai senge welding panguva yegungano.

4.PCB bhodhi uye mudziyo wapera

Yakatengwa mabhodhi ePCB uye zvikamu, nekuda kweiyo nguva yekuverenga yakarebesa, yakakanganiswa nenzvimbo yekuchengetera zvinhu, senge tembiricha, humidity kana gasi rinoparadza, zvichikonzera welding phenomena senge chaiyo welding.

5.Wave soldering midziyo zvinhu

Iyo tembiricha yakanyanya muwave welding furnace inotungamira mukukwidziridza oxidation yeiyo solder zvinhu uye pamusoro peiyo base zvinhu, zvichikonzera kuderedzwa kunamatira kwepasi kune yemvura solder zvinhu. Uyezve, tembiricha yepamusoro inoshatisa zvakare kushata kweiyo base zvinhu, zvichikonzera kuderedzwa kwecapillary kuita uye kushata diffusivity, zvichikonzeresa welding chaiyo.

Nguva yekutumira: Jul-11-2023