1 Nhanganyaya

Mugungano redunhu redunhu, solder paste inodhindwa padhipatimendi redunhu solder pad, uye ipapo zvakasiyana-siyana zvemagetsi zvinonamirwa. Chekupedzisira, mushure mechoto chekuyerera, marata ari mu solder paste anonyungudutswa uye marudzi ese ezvigadzirwa zvemagetsi uye solder pad yedare redunhu zvinosungirirwa pamwechete kuti zvione kuungana kwemagetsi submodules. surfacemounttechnology (sMT) iri kuwedzera kushandiswa mune yakakwira-density packaging zvigadzirwa, senge system level package (siP), ballgridarray (BGA) zvishandiso, uye isina simba Chip, square flat pin-less package (quad aatNo-lead, inonzi QFN) mudziyo.

Nekuda kwehunhu hweiyo solder paste welding process uye zvinhu, mushure mekuti reflow welding yeaya mahombe solder pamusoro pezvishandiso, pachava nemakomba munzvimbo ye solder welding, izvo zvichakanganisa magetsi emagetsi, zvivakwa zvinopisa uye zvemagetsi zvechigadzirwa Performance, uye zvinototungamira mukukundikana kwechigadzirwa, saka, kuvandudza solder paste reflow welding mhango rave hurongwa uye hunyanzvi dambudziko rinofanirwa kunge rakagadziriswa tsvakiridzo yeB. welding mhango, uye yakapa zvigadziriso zvekuvandudza, yakajairwa solder paste reflow welding process welding nzvimbo yeQFN yakakura kupfuura 10mm2 kana welding nzvimbo yakakura kupfuura 6 mm2's bare chip solution yashaikwa.

Shandisa Preformsolder welding uye vacuum reflux furnace welding kuvandudza gomba re weld. Prefabricated solder inoda midziyo yakakosha kunongedza flux. Semuenzaniso, iyo chip inogadziriswa uye yakarereka zvakakomba mushure mekunge chip yaiswa zvakananga pane yakafanogadzirirwa solder. Kana iyo flux mount chip ichiyerera uye yobva yanongedza, maitiro anowedzerwa neaviri reflow, uye mutengo weyakagadzirwa solder uye flux zvinhu wakakwira zvakanyanya kupfuura solder paste.

Vacuum reflux midziyo inodhura zvakanyanya, iyo vacuum yekamuri yakazvimiririra yakadzikira, mutengo wekuita hauna kukwira, uye dambudziko rekupwanya kwerata rakakomba, chinova chinhu chakakosha mukushandiswa kwezvakanyanya-density uye zvidiki-pitch zvigadzirwa. Mupepa iri, zvichibva pane yakajairwa solder paste reflow welding process, itsva yechipiri reflow welding process inogadzirwa uye inounzwa kuti ivandudze iyo welding mhango uye kugadzirisa matambudziko ekubatanidza uye kuputika kwepurasitiki chisimbiso chinokonzerwa newelding cavity.

2 Solder paste kudhinda reflow welding cavity uye kugadzira michina

2.1 Welding cavity

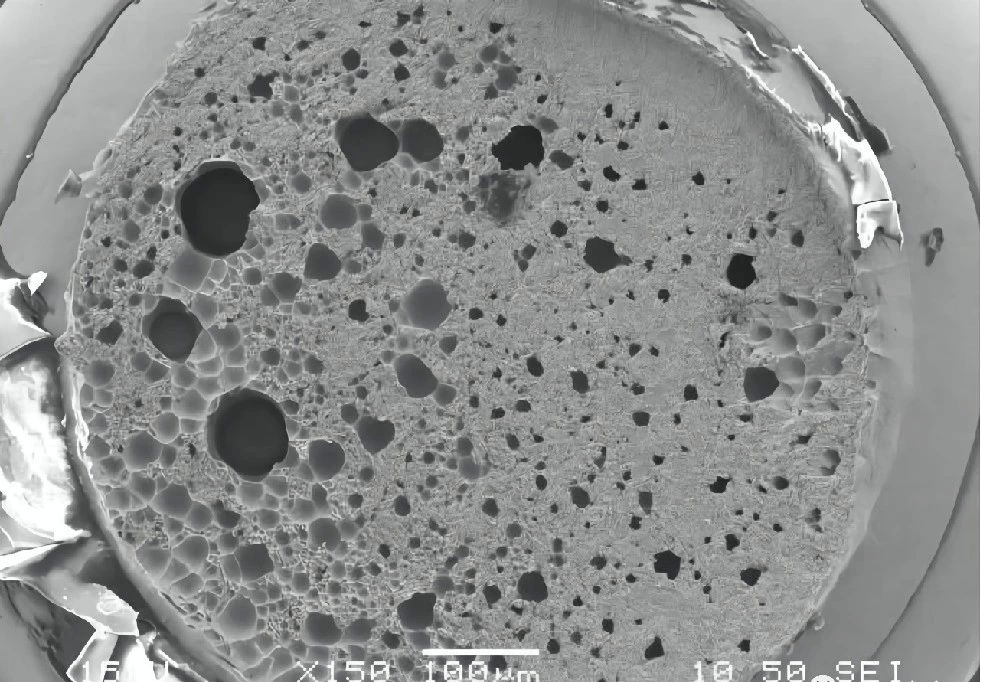

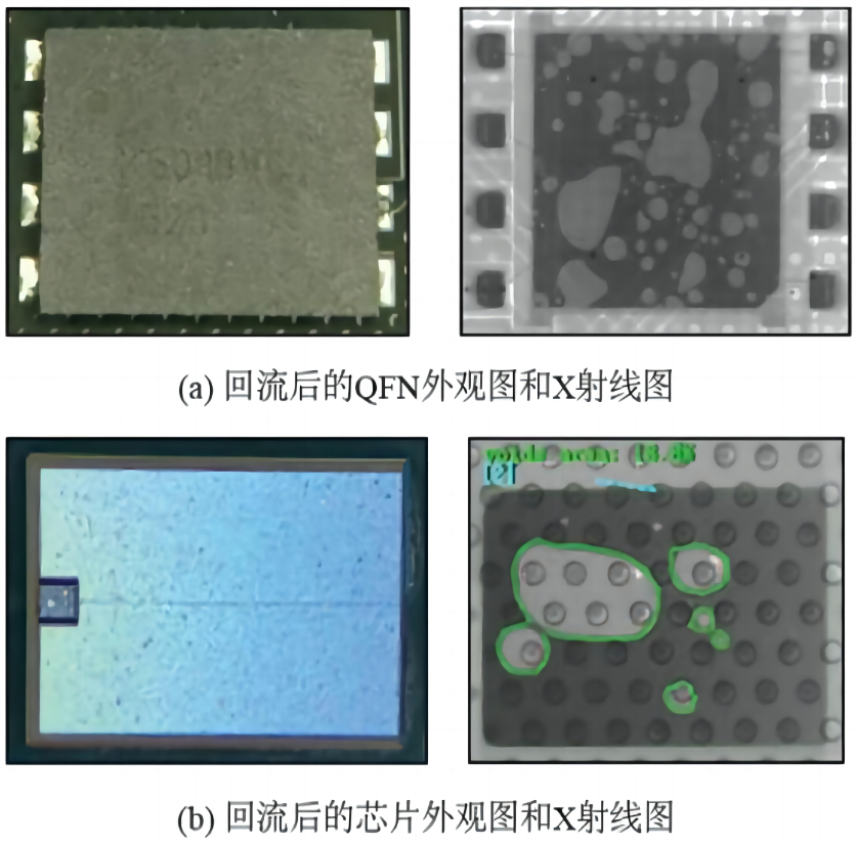

Mushure mekudzorerazve welding, chigadzirwa chakaedzwa pasi pe x-ray. Maburi ari munzvimbo yewelding ane ruvara rwakareruka akawanikwa ari nekuda kwekusakwana solder muwelding layer, sezvakaratidzwa muFigure 1.

X-ray kuonekwa kwegomba rebubble

2.2 Magadzirirwo ekugadzira mhango ye welding

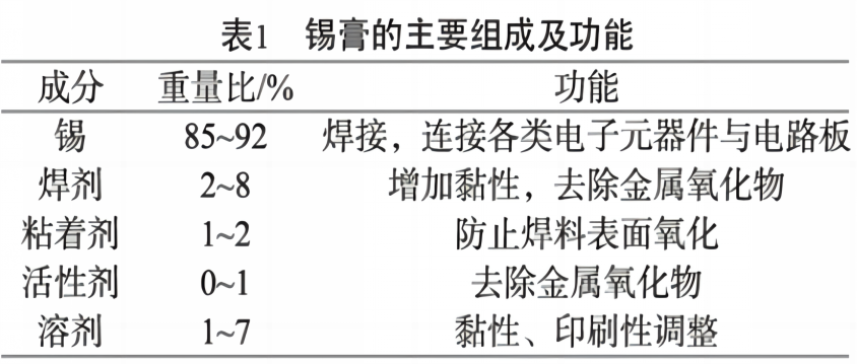

Kutora sAC305 solder paste semuenzaniso, kuumbwa kukuru uye basa rinoratidzwa muTebhu 1. Iyo flux uye tin beads zvakabatanidzwa pamwe chete mu paste shape. Huremu hwehuremu hwetini solder kusvika pa9: 1, uye huwandu hwehuwandu hunenge 1: 1.

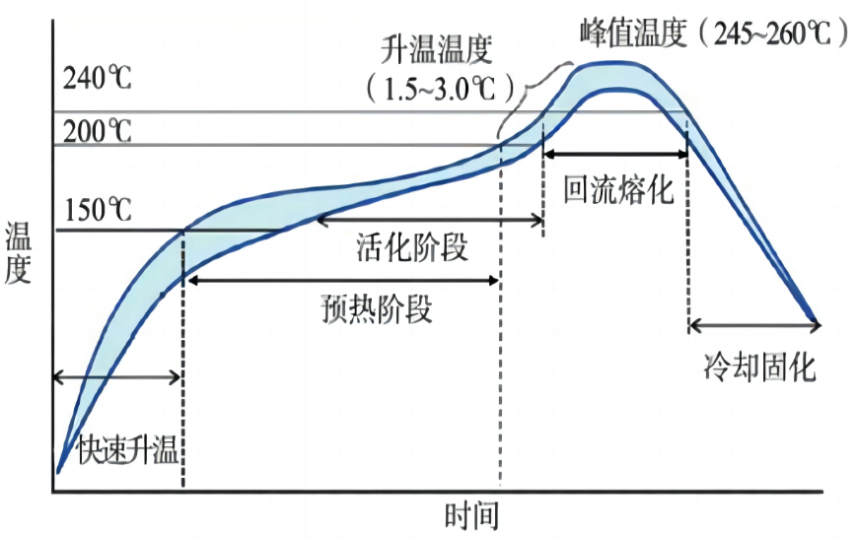

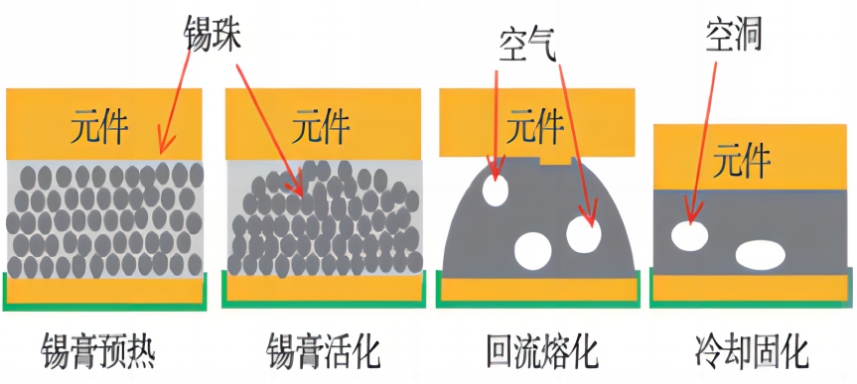

Mushure mokunge solder paste yakadhindwa uye yakasungirirwa nemhando dzakasiyana-siyana dzemagetsi, iyo solder paste ichaita nhanho ina dzepreheating, activation, reflux uye kutonhora kana ichipfuura nepakati reflux choto. Mamiriro eiyo solder paste zvakare akasiyana nekudziya kwakasiyana mumatanho akasiyana, sezvakaratidzwa mumufananidzo 2.

Profile referensi yenzvimbo yega yega ye reflow soldering

Mune preheating uye activation nhanho, iyo inovhuvhuta zvikamu mu flux mune solder paste ichave yakanyanyiswa kuita gasi kana yapiswa. Panguva imwecheteyo, magasi anozogadzirwa kana oxide iri pamusoro peiyo welding layer inobviswa. Mamwe emagasi aya anozonyungudika uye osiya solder paste, uye mabheji anotengeswa anozonyatso kusungirirwa nekuda kwekushata kwekuyerera. Mune reflux nhanho, iyo yakasara flux mu solder paste inoputika nekukurumidza, mabheji etani achanyunguduka, kashoma kekuyerera gasi rinoputika uye mhepo yakawanda pakati pematani mabheji haizopararirwe nekufamba kwenguva, uye zvakasara mugadheni rakanyungudutswa uye pasi pekukakavadzana kwesimbi yakanyungudutswa inobatwa nehamburger uye dhizaini dhizaini uye dhizaini yemagetsi inobatwa. yakaputirwa mugaba remvura inonetsa kupukunyuka chete nekukwira kumusoro Iyo yekunyunguduka kwepamusoro ipfupi. Kana tini rakanyungudutswa ratonhora pasi roita simbi yakasimba, pores anoonekwa muwelding layer uye maburi anogadzirwa anogadzirwa, sezvakaratidzwa muFigure 3.

Schematic dhayagiramu ye void yakagadzirwa ne solder paste reflow welding

Mhedzisiro yewelding cavity ndeyekuti mhepo kana gasi rinoputika rakaputirwa mune solder paste mushure mekunyunguduka harina kubviswa zvachose. Zvinhu zvinofurira zvinosanganisira solder paste zvinhu, solder paste kudhinda chimiro, solder paste kudhinda huwandu, reflux tembiricha, reflux nguva, welding size, chimiro uye zvichingodaro.

3. Verification yekufurira zvinhu zve solder paste kudhinda reflow welding maburi

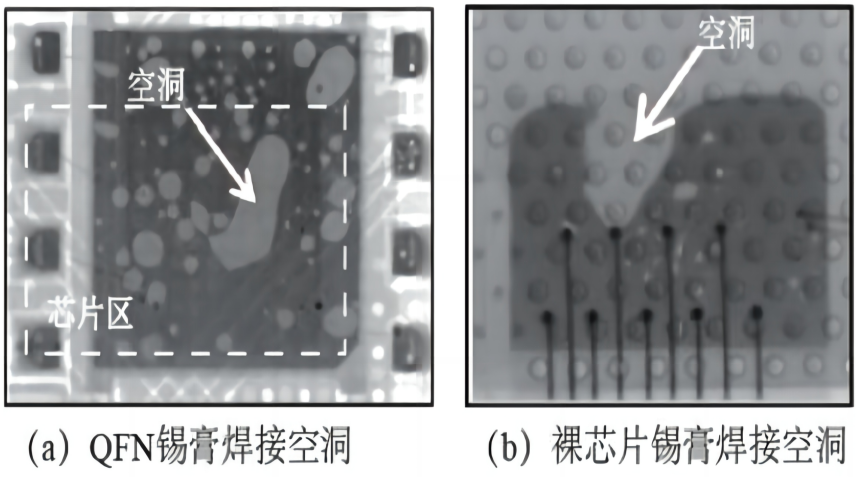

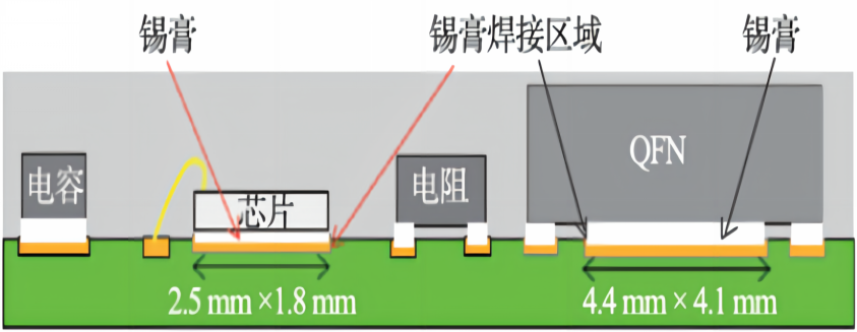

QFN uye bare chip bvunzo dzakashandiswa kusimbisa zvikonzero zvikuru zve reflow welding voids, uye kutsvaga nzira dzekuvandudza reflow welding voids yakadhindwa nesolder paste. QFN uye bare chip solder paste reflow welding product profile inoratidzwa muFigure 4,QFN welding surface size is 4.4mmx4.1mm, welding surface is tinned layer (100% pure tin); Saizi yewelding ye bare chip ndeye 3.0mmx2.3mm, iyo welding layer yakapushwa nickel-vanadium bimetallic layer, uye iyo yepamusoro layer ivanadium. Iyo welding pad ye substrate yaive electroless nickel-palladium goridhe-kunyura, uye ukobvu hwaive 0.4μm/0.06μm/0.04μm. SAC305 solder paste inoshandiswa, solder paste printing equipment is DEK Horizon APix, reflux furnace equipment ndeye BTUPyramax150N, uye x-ray midziyo iDAGExD7500VR.

QFN uye isina chip welding mifananidzo

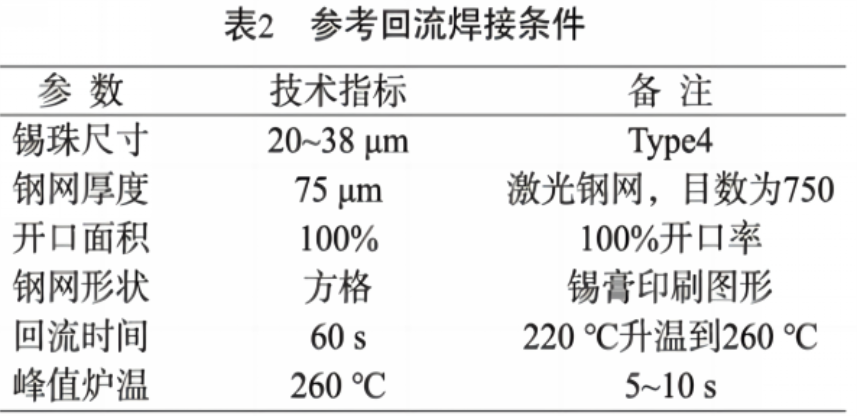

Kufambisa kuenzanisa kwemhedzisiro yebvunzo, reflow welding yakaitwa pasi pemamiriro ari muTafura 2.

Reflow welding mamiriro tafura

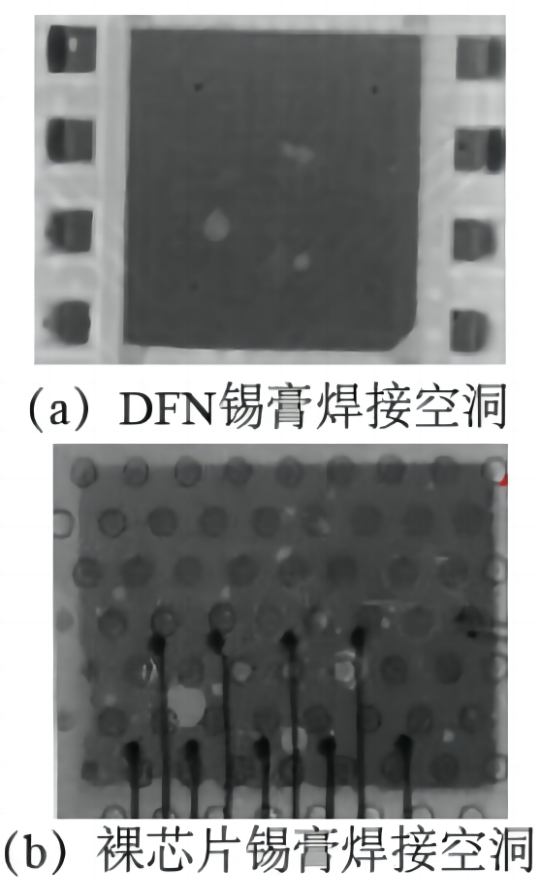

Mushure mekuiswa kwepamusoro uye reflow welding kwapera, iyo welding layer yakaonekwa neX-ray, uye zvakaonekwa kuti pane makomba mahombe muwelding layer pazasi peQFN uye isina chip, sezvakaratidzwa mumufananidzo 5.

QFN uye Chip Hologram (X-ray)

Sezvo tin bead size, simbi mesh ukobvu, kuvhura nzvimbo chiyero, simbi mesh chimiro, reflux nguva uye peak tembiricha yevira zvese zvinokanganisa reflow welding voids, kune zvakawanda zvinofurira zvinhu, izvo zvinozosimbiswa zvakananga neDOE bvunzo, uye huwandu hwemapoka ekuyedza huchave hwakanyanya. Izvo zvinodikanwa kukurumidza kuongorora uye kuona izvo zvikuru zvinopesvedzera zvinhu kuburikidza nekuenzanisa bvunzo bvunzo, uye wobva wawedzera optimize hukuru hwekufurira zvinhu kuburikidza neDOE.

3.1 Zviyero zvemaburi emasolder uye solder namira tin bead

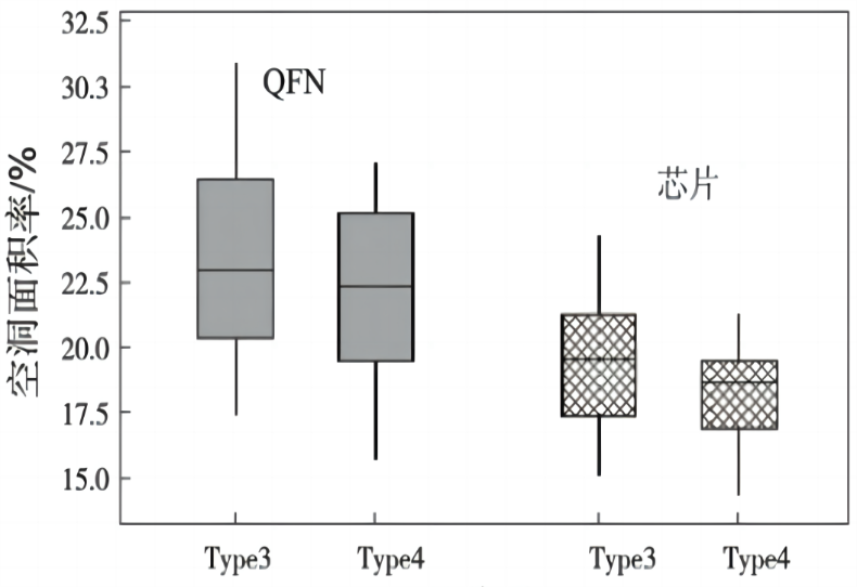

Ne type3 (bead size 25-45 μm)SAC305 solder paste bvunzo, mamwe mamiriro anoramba asina kuchinjika. Mushure mekuyerera zvakare, maburi ari mushizha anoyerwa uye anoenzaniswa netype4 solder paste. Zvinoonekwa kuti maburi ari solder layer haana kunyanya kusiyana pakati pemhando mbiri dze solder paste, zvichiratidza kuti solder paste ine siyana bead saizi haina pesvedzero iri pachena pamaburi ari solder layer, iyo isiri inofurira, sezvakaratidzwa muFIG. 6 Sezvakaratidzwa.

Kuenzanisa kwesimbi yesimbi poda maburi ane akasiyana particle saizi

3.2 Hukobvu hwewelding mhango uye yakadhindwa mesh yesimbi

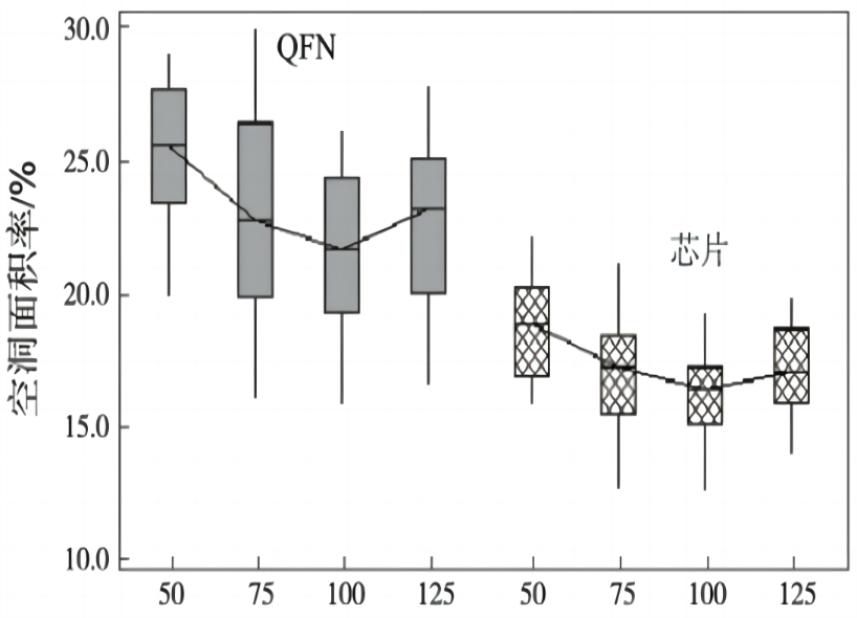

Mushure mekudzokazve, nzvimbo yegomba yewelded layer yakayerwa nesimbi yakadhindwa mesh nehupamhi hwe50 μm, 100 μm uye 125 μm, uye mamwe mamiriro akaramba asina kuchinjwa. Zvakaonekwa kuti mhedzisiro yehukobvu hwakasiyana hwesimbi mesh (solder paste) paQFN yakafananidzwa neyeiyo yakadhindwa mesh yesimbi nehupamhi hwe75 μm Sezvo ukobvu hwesimbi mesh hunowedzera, nzvimbo yemhango inoderera zvishoma nezvishoma. Mushure mekusvika kune imwe gobvu (100μm), iyo nzvimbo yegomba ichadzokera kumashure uye inotanga kuwedzera nekuwedzera kwehupamhi hwesimbi mesh, sezvakaratidzwa mumufananidzo 7.

Izvi zvinoratidza kuti kana huwandu hwe solder paste huchiwedzerwa, iyo tini yemvura ine reflux yakafukidzwa nechip, uye kubuda kwemhepo yakasara kupukunyuka kunongotetepa pamativi mana. Kana huwandu hwesolder paste hwashandurwa, kubuda kwemhepo yakasara kupukunyuka kunowedzerawo, uye kuputika kwemhepo kwakaputirwa mumarata emvura kana gasi rinoputika riri kubuda mugasi remvura kuchaita kuti tini remvura riparare kutenderera QFN uye chip.

Muedzo wakaona kuti nekuwedzera kwekukora kwesimbi mesh, kuputika kwebubble kunokonzerwa nekupukunyuka kwemhepo kana gasi rinoputika richawedzerawo, uye mukana wekupfapfaidza kwerata kutenderera QFN uye chip ichawedzerawo zvinoenderana.

Kuenzanisa kwemakomba musimbi mesh yehupamhi hwakasiyana

3.3 Nharaunda chiyero chewelding cavity uye simbi mesh kuvhurwa

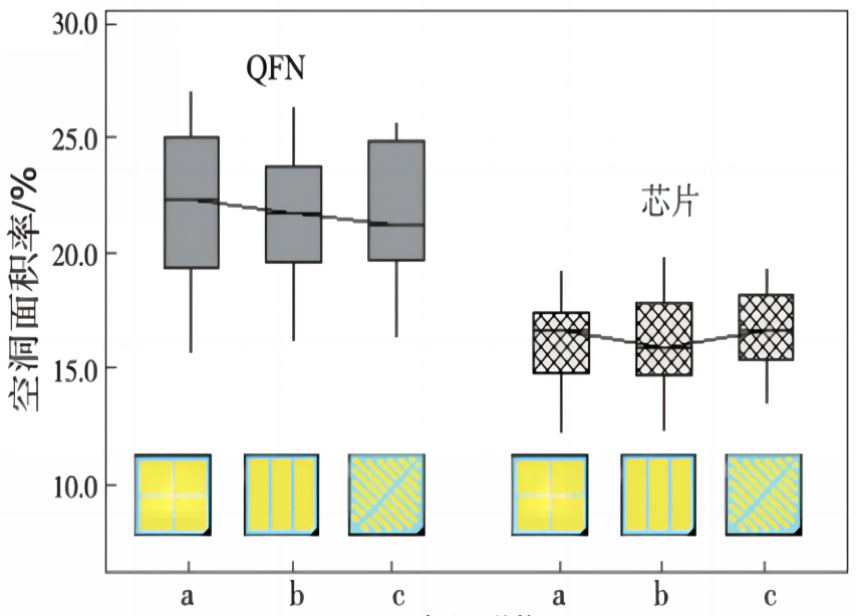

Iyo yakadhindwa mesh yesimbi ine mukana wekuvhura we100%, 90% uye 80% yakaedzwa, uye mamwe mamiriro akaramba asina kuchinjwa. Mushure mekufefetera, nzvimbo yemhango yewalded layer yakayerwa ichienzaniswa neyakadhindwa mesh yesimbi ine 100% yekuvhura rate. Zvakaonekwa kuti pakanga pasina mutsauko wakakosha mugomba reiyo welded layer pasi pemamiriro ekuvhura kwe100% uye 90% 80%, sezvakaratidzwa mumufananidzo 8.

Cavity kuenzanisa yenzvimbo dzakasiyana dzekuvhura dzakasiyana simbi mesh

3.4 Welded mhango uye yakadhindwa simbi mesh chimiro

Nekudhinda chimiro bvunzo ye solder paste ye strip b uye inclined grid c, mamwe mamiriro anoramba asina kuchinjika. Mushure mekuyerera, nzvimbo yegomba yewelding layer inoyerwa nekuenzaniswa neinodhinda chimiro chegridi a. Inowanikwa kuti hapana mutsauko wakakosha mugomba rewelding layer pasi pemamiriro egridi, mitsetse uye yakarerekera grid, sezvakaratidzwa mumufananidzo 9.

Kuenzanisa kwemakomba mune dzakasiyana nzira dzekuvhura dzesimbi mesh

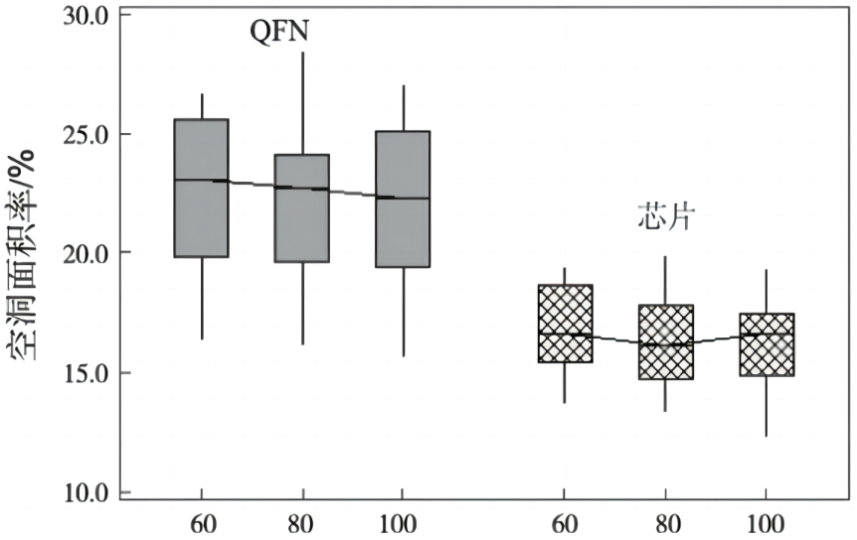

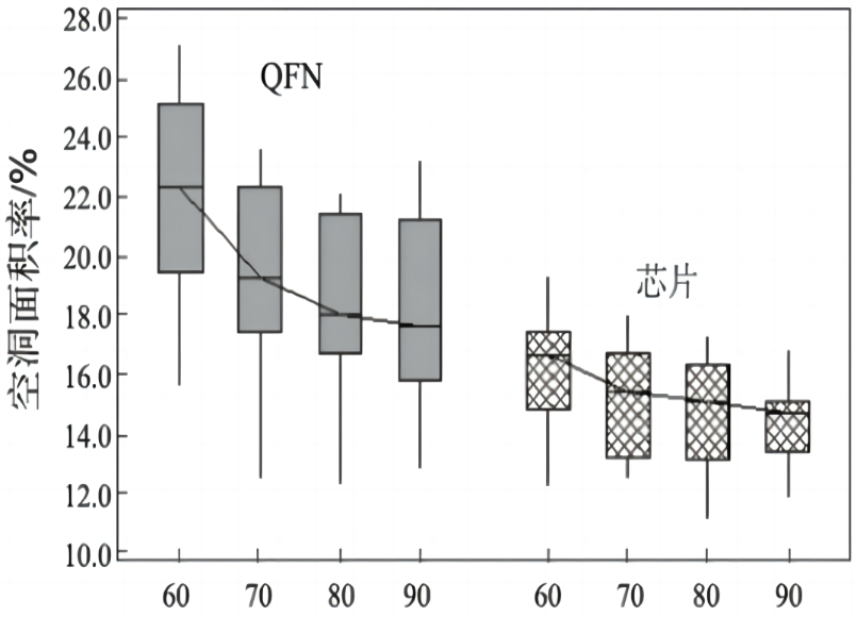

3.5 Welding cavity uye reflux nguva

Mushure menguva refu reflux nguva (70 s, 80 s, 90 s) bvunzo, mamwe mamiriro anoramba asina kuchinjika, gomba muwelding layer yakayerwa mushure meiyo reflux, uye kana ichienzaniswa neiyo reflux nguva ye60 s, zvakaonekwa kuti nekuwedzera kwenguva reflux, iyo welding gomba nzvimbo yakadzikira, asi kuderedzwa kwegomba rekutapudza kwakaderedzwa nekuwedzera kweiyo nguva inoratidzwa. muchiitiko chenguva isina kukwana reflux, kuwedzera nguva yereflux inobatsira kune yakazara yakazara yemhepo yakaputirwa musimbi yakanyungudutswa yemvura, asi mushure mokunge nguva yereflux inowedzera kune imwe nguva, mhepo yakaputirwa mumvura yemvura yakaoma kuputika zvakare. Reflux nguva ndechimwe chezvinhu zvinokanganisa welding cavity.

Kuenzanisa kusingaenzaniswi kwehurefu hwakasiyana hwenguva reflux

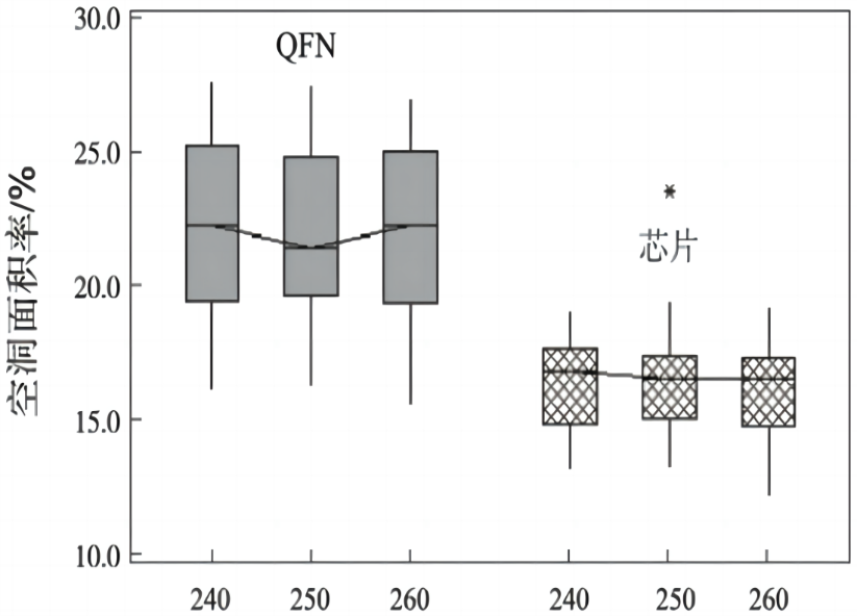

3.6 Welding mhango uye peak tembiricha yevira

Iine 240 ℃ uye 250 ℃ peak tembiricha tembiricha uye mamwe mamiriro asina kuchinjika, mhango yenzvimbo yewelded layer yakayerwa mushure mekuyerera, uye ichienzaniswa ne260 ℃ peak tembiricha yevira, zvakaonekwa kuti pasi peakasiyana peak choto tembiricha mamiriro, gomba reiyo welded layer yeQFN inoratidzira 1 zvakasiyana zvakanyanya. peak tembiricha yevira haina mhedzisiro iri pachena paQFN uye gomba mune welding layer yechip, iyo isiri inofurira chinhu.

Kuenzanisa kusina maturo kwekupisa kwepamusoro kwakasiyana

Iwo maedzo ari pamusoro anoratidza kuti zvakakosha zvinokanganisa weld layer cavity yeQFN uye chip inguva reflux uye simbi mesh ukobvu.

4 Solder paste kudhinda reflow welding cavity kunatsiridza

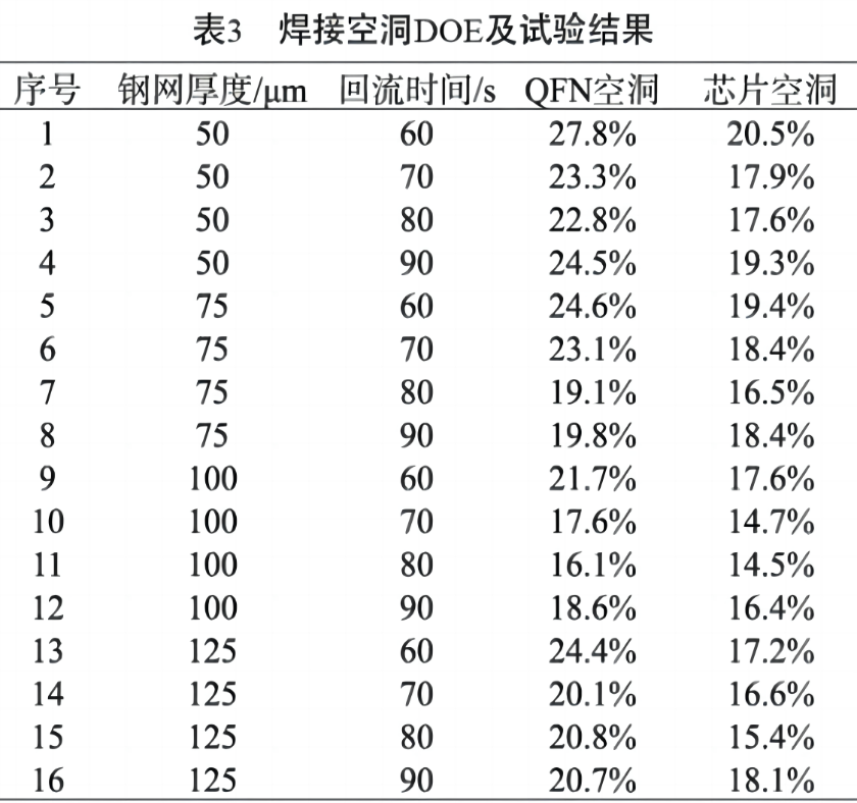

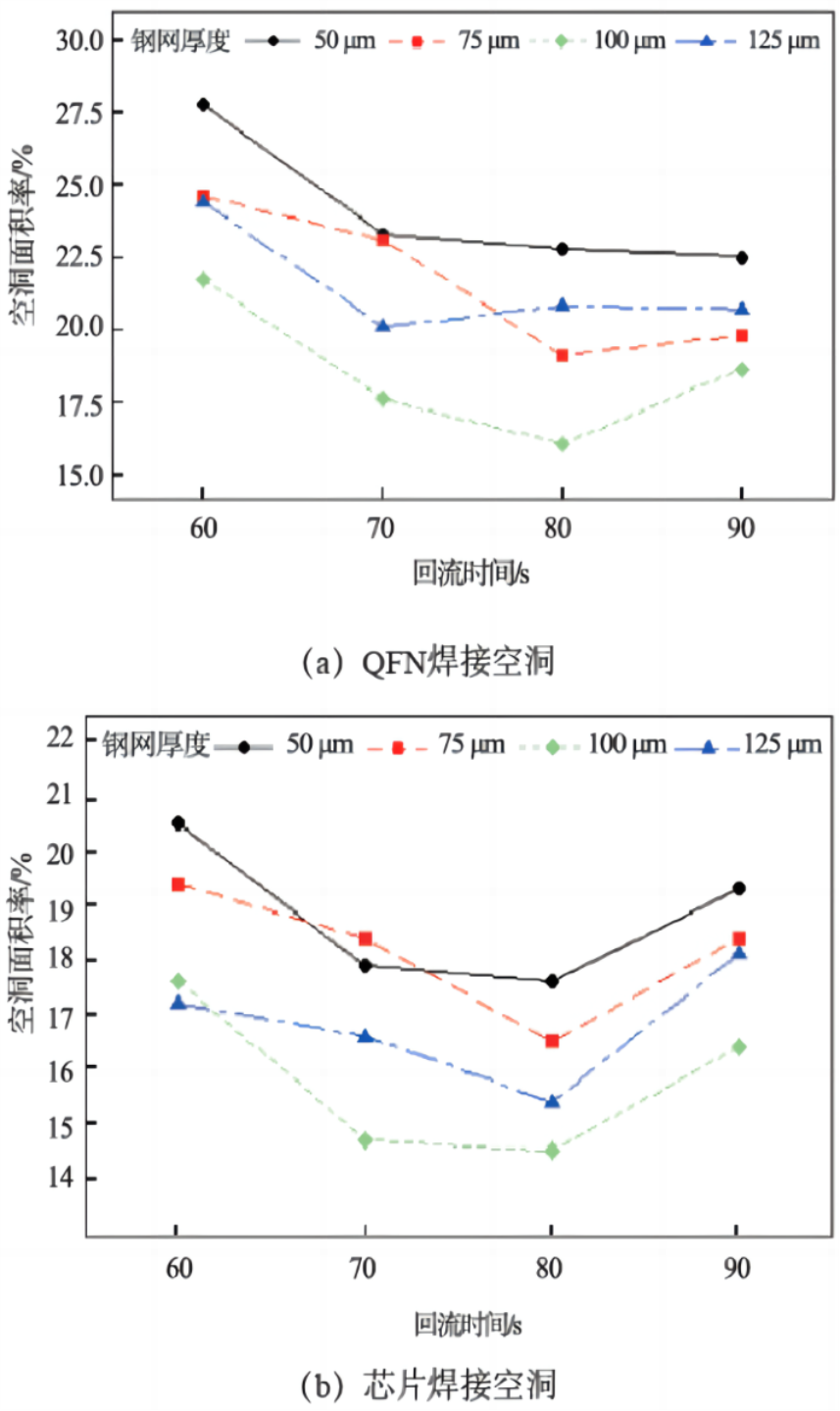

4.1DOE bvunzo yekuvandudza welding cavity

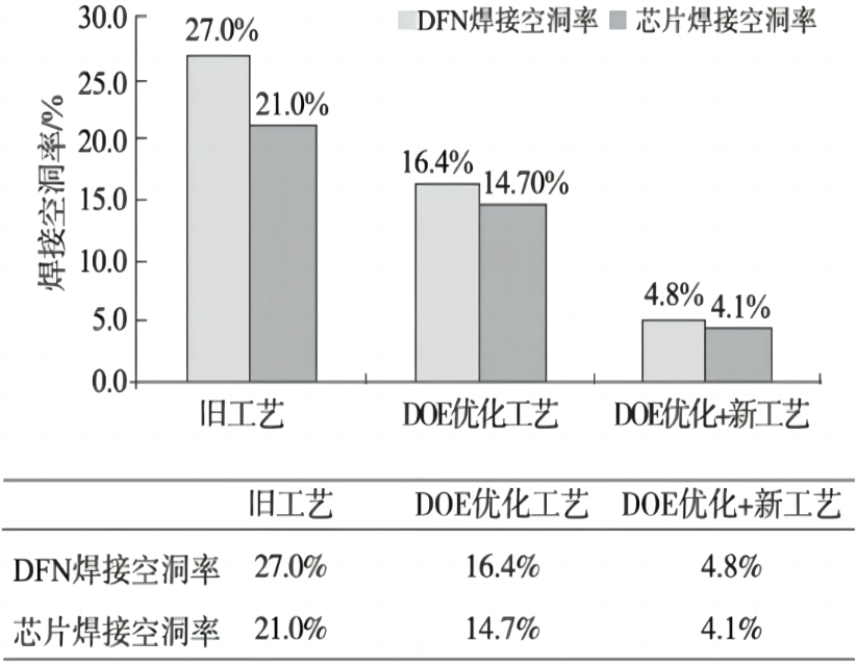

Gomba muwelding layer yeQFN uye chip yakagadziridzwa nekuwana iyo yakakwana kukosha kweiyo huru inofurira zvinhu (reflux nguva uye simbi mesh ukobvu). Solder paste yaive SAC305 type4, simbi mesh shape yaive grid type (100% yekuvhura degree), tembiricha yechoto yepamusoro yaive 260 ℃, uye mamwe mamiriro ebvunzo aive akafanana neaya emidziyo yekuyedza. Kuongorora kweDOE nemigumisiro yakaratidzwa muTebhu 3. Izvo zvinokonzerwa nesimbi mesh thickening uye reflux nguva paQFN uye chip welding holes inoratidzwa muMufananidzo 12. Kuburikidza nekuongorora kwekubatana kwezvinhu zvinonyanya kupesvedzera zvinhu, Inowanikwa kuti kushandisa 100 μm metal mesh thickness uye 80 s reflux nguva inogona kuderedza zvakanyanya welding uye chip cavity yeQF. Welding cavity rate yeQFN yakaderedzwa kubva pahupamhi hwe27.8% kusvika 16.1%, uye welding cavity rate yechip inoderedzwa kubva pakakwirira 20.5% kusvika 14.5%.

Muyedzo, zvigadzirwa zana zvakagadzirwa pasi pemamiriro akakwana (100 μm simbi mesh ukobvu, 80 s reflux nguva), uye welding cavity rate ye100 QFN uye chip yakayerwa zvisina tsarukano. Avhareji welding cavity rate yeQFN yaive 16.4%, uye avhareji welding cavity rate ye chip yaive 14.7% Iyo weld cavity rate yechip uye chip zviri pachena kuti yakaderedzwa.

4.2 Iyo nyowani maitiro inovandudza welding cavity

Iyo chaiyo yekugadzira mamiriro uye bvunzo inoratidza kuti kana welding mhango nzvimbo iri pazasi pe chip iri pasi pe10%, iyo chip cavity chinzvimbo chinoputika dambudziko hachizoitika panguva yekutungamirira bonding uye kuumbwa. Iyo maitiro maparamendi akagadziridzwa neDOE haagone kusangana nezvinodiwa zvekuongorora nekugadzirisa maburi mune yakajairwa solder paste reflow welding, uye welding cavity nzvimbo chiyero chechip chinoda kuderedzwa.

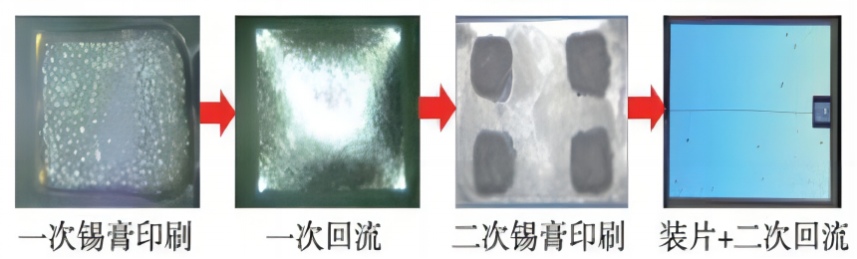

Sezvo chip yakavharwa pane solder ichidzivirira gasi mune solder kutiza, chiyero chegomba pazasi pechiputi chinowedzerwa nekubvisa kana kuderedza solder yakavharwa gasi. Nzira itsva ye reflow welding ine maviri solder paste printing inogamuchirwa: imwe solder paste kudhinda, imwe reflow isingafukidze QFN uye isina chip ichibudisa gasi mune solder; Iyo chaiyo maitiro echipiri solder paste kudhinda, chigamba uye yechipiri reflux inoratidzwa muMufananidzo 13.

Kana iyo 75μm yakakora solder paste inodhindwa kekutanga, yakawanda yegasi musolder isina chip cover inobuda kubva pamusoro, uye ukobvu mushure mereflux inenge 50μm. Mushure mekupedzwa kweyekutanga reflux, madiki masikweya anodhindwa pamusoro peiyo yakatonhodzwa solidified solder (kuitira kudzikisa huwandu hwesolder paste, kuderedza huwandu hwegasi spillover, kuderedza kana kubvisa solder spatter), uye solder paste nehupamhi hwe50 μm (iyo iri pamusoro bvunzo mhinduro inoratidza kuti 100 μm ndiyo yakanakisa dhinda 50, saka iyo 100 μm ndiyo yakanakisa kudhinda. μm = 50 μm), wozoisa chip, uye wozodzoka kuburikidza ne80 s. Inenge isina gomba mu solder mushure mekutanga kudhindwa uye kuyerera, uye solder paste mukudhinda kwechipiri idiki, uye gomba rewelding idiki, sezvakaratidzwa muFigure 14.

Mushure mekudhinda kuviri kwe solder paste, hollow kudhirowa

4.3 Kuongororwa kweiyo welding cavity maitiro

Kugadzirwa kwe2000 zvigadzirwa (ukobvu hwekutanga kudhinda simbi mesh ndeye 75 μm, ukobvu hwechipiri kudhinda simbi mesh ndeye 50 μm), mamwe mamiriro asina kuchinjika, chiyero chekuyeresa che500 QFN uye chip welding cavity rate, yakawana kuti iyo nzira nyowani mushure mekutanga reflux hapana mhango, mushure mechipiri reflux welding chiyero cheQFN chiyero chepamusoro che 4 mhango. chip ndeye 4.1%. Kuenzaniswa neyokutanga-single-paste printing welding process uye DOE optimized process, iyo welding cavity yakaderedzwa zvakanyanya, sezvakaratidzwa muMufananidzo 15. Hapana chip cracks chakawanikwa mushure mekuedzwa kwekushanda kwezvinhu zvose.

5 Pfupiso

Iko optimization ye solder paste kudhinda huwandu uye reflux nguva inogona kuderedza welding cavity nzvimbo, asi welding cavity rate ichiri yakakura. Kushandisa maviri solder paste kudhinda reflow welding matekiniki anogona zvinobudirira uye kuwedzera welding cavity rate. Iyo welding nzvimbo yeQFN circuit bare chip inogona kuita 4.4mm x4.1mm uye 3.0mm x2.3mm zvakateerana mukugadzirwa kwakawanda Iyo cavity rate ye reflow welding inodzorwa pazasi 5%, iyo inovandudza kunaka uye kuvimbika kwereflow welding. Tsvagiridzo iri mubepa rino inopa chirevo chakakosha chekuvandudza dambudziko rewelding cavity yenzvimbo hombe welding nzvimbo.

Nguva yekutumira: Jul-05-2023