SMT adhesive, inozivikanwawo se SMT adhesive, SMT red adhesive, inowanzo tsvuku (zvakare yero kana chena) paste yakagovaniswa nehardener, pigment, solvent uye zvimwe zvinonamira, zvinonyanya kushandiswa kugadzirisa zvikamu pabhodhi rekudhinda, rinowanzo kugoverwa nekuparadzira kana simbi skrini yekudhinda nzira. Mushure mekuisa zvikamu, zviise muchoto kana reflow furnace yekupisa nekuomesa. Musiyano uripo pakati payo uye solder paste ndeyekuti inoporeswa mushure mekupisa, kutonhora kwayo kunosvika 150 ° C, uye haizonyungudika mushure mekudziyisazve, ndiko kuti, kupisa kwekuomesa kwechigamba hakuchinjiki. Iko kushandiswa kweSMT adhesive kuchasiyana nekuda kwemamiriro ekurapa ekupisa, chinhu chakabatana, midziyo inoshandiswa, uye nharaunda yekushanda. Iyo yekunamatira inofanirwa kusarudzwa zvinoenderana neyakadhindwa yedunhu bhodhi musangano (PCBA, PCA) maitiro.

Hunhu, mashandisirwo uye tarisiro yeSMT chigamba chinonamira

SMT dzvuku glue imhando yepolymer mukomboni, iwo makuru maficha ndiwo akadzika zvinhu (kureva, iyo huru yakakwira molecular material), filler, kurapa mumiririri, zvimwe zvinowedzera uye zvichingodaro. SMT red glue ine viscosity fluidity, tembiricha maitiro, wetting maitiro uye zvichingodaro. Zvinoenderana nehunhu uhu hwehudyu dzvuku, mukugadzirwa, chinangwa chekushandisa dzvuku glue ndechekuita kuti zvikamu zvinyatsonamira kumusoro kwePCB kudzivirira kuti irege kudonha. Naizvozvo, chigamba chinonamirwa ndechekushandiswa kwakachena kwezvisingakoshese zvigadzirwa, uye iko zvino nekuenderera mberi kwekuvandudzwa kwePCA dhizaini uye maitiro, kuburikidza negomba reflow uye kaviri-sided reflow welding zvave kuitika, uye PCA yekumisikidza maitiro uchishandisa chigamba chekunamira chiri kuratidza maitiro ezvishoma uye zvishoma.

Chinangwa chekushandisa SMT adhesive

① Dzivirira zvinhu kubva pakudonha mu wave soldering (wave soldering process). Paunenge uchishandisa wave soldering, zvikamu zvinogadziriswa pabhodhi rakadhindwa kudzivirira kuti zvikamu zvirege kudonha kana bhodhi rakadhindwa richipfuura nepakati pe solder groove.

② Dzivirira rumwe rutivi rwezvikamu kubva pakudonha mu reflow welding (double-sided reflow welding process). Muchikamu cheviri-side reflow welding process, kuitira kudzivirira michina mikuru padivi rakatengeswa kuti isadonha nekuda kwekunyungudika kwekupisa kweiyo solder, SMT chigamba glue chinofanira kuitwa.

③ Dzivirira kutamiswa uye kumira kwezvikamu (reflow welding process, pre-coating process). Inoshandiswa mune reflow welding maitiro uye pre-coating maitiro ekudzivirira kutamiswa uye riser panguva yekukwira.

④ Maka (wave soldering, reflow welding, pre-coating). Mukuwedzera, kana mabhodhi akadhindwa uye zvikamu zvakashandurwa mumabheti, chigamba chekunamatira chinoshandiswa pakumaka.

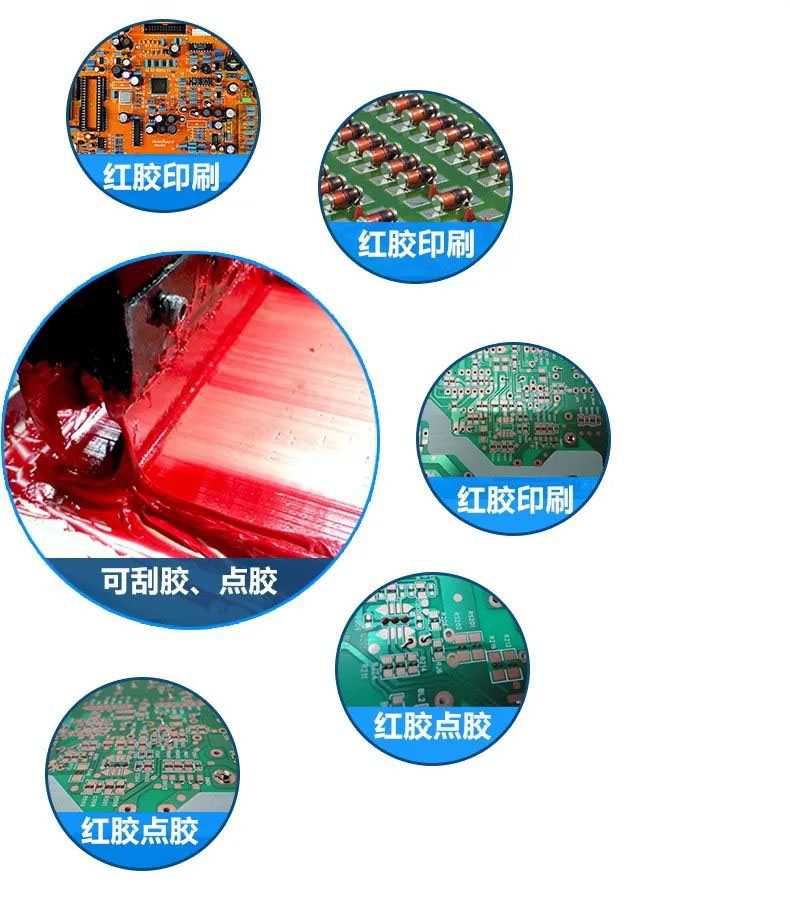

SMT adhesive inokamurwa zvinoenderana nemaitiro ekushandisa

a) Rudzi rwekukwenya: saizi inoitwa kuburikidza nekudhinda uye kukwenya maitiro esimbi mesh. Iyi nzira ndiyo inonyanya kushandiswa uye inogona kushandiswa zvakananga pane solder paste press. Makomba esimbi mesh anofanirwa kutariswa zvichienderana nerudzi rwezvikamu, kuita kwe substrate, ukobvu uye saizi uye chimiro chemakomba. Zvakanakira zvaro kukurumidza kukurumidza, kushanda kwakanyanya uye mutengo wakaderera.

b) Rudzi rwekugovera: Iyo glue inoshandiswa pane yakadhindwa redunhu bhodhi nekuparadzira michina. Special dispensing equipment inodiwa, uye mutengo wacho wakakwira. Midziyo yekuparadzira iko kushandiswa kwemhepo yakamanikidzwa, iyo tsvuku glue kuburikidza neakakosha musoro wekugovera kune substrate, saizi yeglue point, yakawanda sei, nenguva, yekumanikidza chubhu dhayamita uye mamwe ma paramita ekudzora, muchina wekuparadzira une basa rinoshanduka. Kune zvikamu zvakasiyana, tinogona kushandisa misoro yakasiyana yekuparadzira, kuisa maparamita ekuchinja, iwe unogona zvakare kushandura chimiro uye huwandu hweglue point, kuitira kuti uwane mhedzisiro, zvakanakira zviri nyore, zvinochinjika uye zvakagadzikana. Kukanganisa kuri nyore kuve newaya kudhirowa uye mabhuru. Tinogona kugadzirisa ma parameter ekushanda, kumhanya, nguva, mhepo yekumanikidza, uye tembiricha kuti tideredze zvikanganiso izvi.

SMT Patching Typical CICC

chenjera:

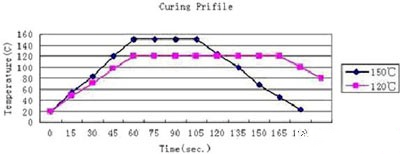

1. Iyo yakakwirira yekupisa tembiricha uye kurebesa nguva yekurapa, kusimba kwesimba rekunamira.

2. Nokuti kutonhora kwechigamba glue kuchachinja nehukuru hwezvikamu zve substrate uye nzvimbo yekunamatira, tinokurudzira kutsvaga zvakanyanya kuoma mamiriro ezvinhu.

SMT chigamba glue kuchengetedza

Inogona kuchengetwa kwemazuva manomwe patembiricha yekamuri, chengetedzo yakakura kupfuura June isingasviki 5 ° C, uye inogona kuchengetwa kwemazuva anopfuura makumi matatu pa5-25 ° C.

SMT chigamba chingamu manejimendi

Nekuti iyo SMT chigamba tsvuku glue inokanganiswa nekupisa, hunhu hwe viscosity, liquidity, uye kunyorova kweSMT, iyo SMT chigamba tsvuku glue inofanira kunge iine mamwe mamiriro uye yakajairwa manejimendi.

1) Gluu tsvuku inofanira kunge iine nhamba yekuyerera, uye nhamba zvichienderana nehuwandu hwekudyisa, zuva, uye marudzi.

2) Gluu yakatsvuka inofanira kuchengetwa mufiriji ye2 kusvika ku8 ° C kudzivirira maitiro emhando nekuda kwekushanduka kwekushisa.

3) Red glue kudzoreredza kunoda maawa mana pane tembiricha yekamuri, uye inoshandiswa mukurongeka kwekutanga.

4) Nezve mapoinzi ekuzadza mashandiro, iyo glue chubhu tsvuku glue inofanira kugadzirwa. Nokuda kweglue tsvuku isina kushandiswa panguva imwe chete, inofanira kudzorerwa mufiriji kuti ichengetedze.

5) Zadza fomu rekurekodha rekodhi nenzira kwayo. Nguva yekudzorera uye yekudziya inofanira kushandiswa. Mushandisi anofanira kusimbisa kuti kudzoreredza kwapera kusati kwashandiswa. Kazhinji, glue tsvuku haigone kushandiswa.

SMT chigamba glue maitiro maitiro

Kusimba kwekubatanidza: SMT chigamba glue inofanira kuva nesimba rakasimba rekubatanidza. Mushure mekuomeswa, tembiricha ye weld melt haina kupepetwa.

Point coating: Parizvino, nzira yekugovera yebhodhi rekudhinda inonyanya kushandiswa, saka inodiwa kuve nekutevera kuita:

① Gadzirisa kune akasiyana zvimiti

② Zviri nyore kuseta kuwanikwa kwechimwe nechimwe chikamu

③ Ingo gadzirisa kune zvinotsiva chikamu mhando

④ Point coating yakagadzikana

Gadzirisa kumichina inomhanya-mhanya: Iyo chigamba glue ikozvino inofanira kusangana neyakakwirisa-yekumhanyisa coating uye yakakwirira-yekumhanya chigamba muchina. Kunyanya, iyo yakakwirira-yekumhanya dot inodhirowa isina kudhirowa, uye kana yakakwira-speed paste yakaiswa, iyo yakadhindwa bhodhi iri munzira yekufambisa. Iko kunamira kwematepi chingamu kunofanirwa kuve nechokwadi kuti chikamu hachifambi.

Ritting uye kudonha: Kana chigamba cheglue chasvibiswa padhi, chikamu chacho hachigoni kubatanidzwa nemagetsi ekubatanidza nebhodhi rakadhindwa. Kudzivirira kusvibisa mapedhi.

Kupora tembiricha yakaderera: Kana ichiomesa, tanga washandisa peak-welded isingakwane kupisa-resistant kuisirwa zvikamu kuti zvive welded, saka zvinodikanwa kuti kuomeswa kwemamiriro kunofanirwa kusangana nekushisa kwakaderera uye nguva pfupi.

Self-adjustability: Mukugadzirisa zvakare uye pre-coating process, patch glue inosimbiswa uye yakagadziriswa zvikamu zvisati zvanyungudutswa weld, saka inodzivisa kunyura kwemeta uye kuzvigadzirisa. Nekuda kweichi chinhu, vagadziri vakagadzira self-adjustable patch glue.

SMT chigamba glue zvakajairika matambudziko, kukanganisa uye kuongorora

Kusundira kusina kukwana

Izvo zvinodikanwa zvekusimbisa simba re0603 capacitor i1.0kg, kuramba kuri 1.5kg, simba rekukanda re0805 capacitor i1.5kg, uye kuramba kuri 2.0kg.

Kazhinji zvinokonzerwa nezvikonzero zvinotevera:

1. Guruu isina kukwana.

2. Hapana 100% kusimbiswa kwecolloid.

3. Mabhodhi ePCB kana zvikamu zvakasvibiswa.

4. Iyo colloid pachayo ichiri crispy uye haina simba.

Tentile isina kugadzikana

Iyo 30ml sirinji glue inoda kurohwa nekumanikidza makumi ezviuru zvenguva kuti ipedze, saka inodiwa kuve neakanyanya kunaka tactileness pachayo, zvikasadaro zvinokonzeresa kusagadzikana glue mapoinzi uye kushomeka guruu. Kana welding, chikamu chinodonha. Pane zvinopesana, glue yakawandisa, kunyanya kune zvidiki zvikamu, zviri nyore kunamatira padhi, zvichitadzisa magetsi kubatana.

Kusakwana kana kuvuza

Zvikonzero uye matanho ekupikisa:

1. Bhodhi remambure rekudhinda hariwanzogezwa, uye ethanol inofanira kugezwa maawa masere oga oga.

2. Colloid ine tsvina.

3. Kuvhura kwemeshi hakusi kunzwisisika kana kuduku kana kuti glue gasi rinodzvinyirira rakanyanya kuduku.

4. Kune mabubbles mucolloid.

5. Sunga musoro kuti uvhare, uye pakarepo uchenese muromo werabha.

6. Kupisa kwekushisa kwenzvimbo ye tepi hakuna kukwana, uye kutonhora kwepombi kunofanira kuiswa pa 38 ° C.

Brushed

Izvo zvinonzi brushed ndezvokuti chigamba hachina kuputsika kana dicture, uye chigamba chakabatanidzwa mune dot -headed direction. Kune mamwe mawaya, uye chigamba glue chakavharwa pane yakadhindwa padhi, izvo zvinokonzeresa kushomeka. Kunyanya kana saizi yakakura, chiitiko ichi chinowanzoitika kana ukaisa muromo wako. Kugadziriswa kwechimedu glue mabhurashi kunonyanya kukanganiswa neiyo mainingidzo resin mabhurashi uye marongero eiyo point coating mamiriro:

1. Wedzera kurova kwemvura kuti uderedze kumhanya kwekufamba, asi zvinoderedza yako okisheni yekugadzira.

2. Iyo yakaderera yakaderera viscosity, yakakwirira-kubata zvinhu, iyo diki tsika yekudhirowa, saka edza kusarudza rudzi urwu rwetepi.

3. Wedzera zvishoma kutonhora kweiyo thermal regulator, uye kuigadzirisa kune yakaderera viscosity, yakakwirira-kubata uye degeneration chigamba glue. Panguva ino, nguva yekuchengetedza yechigamba glue uye kumanikidzwa kwemusoro wepombi kunofanirwa kutariswa.

Collapse

Iyo liquidity yechigamba glue inokonzeresa kudonha. Dambudziko rinowanzoitika rekuputsika nderekuti richakonzera kudonha mushure mekuiswa kwenguva refu. Kana iyo chigamba glue ichiwedzerwa kune padhi pane yakadhindwa redunhu bhodhi, zvinokonzeresa kusaina welding. Uye kune izvo zvikamu zvine mapini akareba, hazvigone kubata muviri mukuru wechikamu, izvo zvinokonzeresa kusakwana kunamatira. Naizvozvo, zviri nyore kudonha. Izvo zvinofanotaurwa, saka yekutanga kugadzika kweiyo point coating yakaoma zvakare. Mukupindura izvi, taifanira kusarudza avo vakanga vasiri nyore kudonha. Nekudonha kunokonzerwa nedotted kwenguva yakareba, tinogona kushandisa chigamba glue uye kusimba munguva pfupi yekudzivirira.

Component offset

Component offset chinhu chakashata chinowanzoitika kune yakakwira -speed patch machines. Chikonzero chikuru ndechekuti:

1. Ndiyo offset inogadzirwa negwara reXY apo bhodhi rakadhindwa riri kufamba nekumhanya kukuru. Ichi chiitiko chinowanzoitika pachikamu chine diki glue coating nzvimbo. Chikonzero chinokonzerwa nekunamatira.

2. Izvo zvisingaenderani nehuwandu hweglue pasi pechikamu (somuenzaniso: 2 glue points pasi pe IC, glue point yakakura uye duku glue point). Apo glue rinopisa uye rakasimbiswa, simba racho harina kuenzana, uye imwe mugumo ine chidimbu chiduku cheglue iri nyore kubvisa.

Welding chikamu chepamusoro

Chikonzero chechikonzero chakaoma zvikuru:

1. Kusakwana kusungirirwa kwechigamba glue.

2. Mafungu asati aputirwa, airohwa asati atungidzirwa.

3. Pane zvakawanda zvakasara pane zvimwe zvikamu.

4. High tembiricha kukanganisa colloidity haamiri kupisa tembiricha

Patch glue yakasanganiswa

Vagadziri vakasiyana vakasiyana zvakanyanya mukugadzirwa kwemakemikari. Kushandiswa kwakasanganiswa kunowanzokonzera kukanganisa kwakawanda: 1. Fixed yakaoma; 2. Kusakwana kunamatira; 3. Yakanyanya welded zvikamu pamusoro pepamusoro.

Mhinduro ndeyokuti: kunyatsochenesa mesh, scraper, uye point-headed head, izvo zviri nyore kukonzera kushandiswa kwakasanganiswa kudzivisa kusanganisa kushandiswa kwemhando dzakasiyana dzepatch glue.

Nguva yekutumira: Jun-19-2023