【Dry goods 】 Kuongorora kwakadzama kweSMT nei kushandisa tsvuku glue? (2023 Essence Edition), iwe wakakodzera!

SMT adhesive, inozivikanwawo se SMT adhesive, SMT red adhesive, inowanzo tsvuku (zvakare yero kana chena) paste yakagovaniswa nehardener, pigment, solvent uye zvimwe zvinonamira, zvinonyanya kushandiswa kugadzirisa zvikamu pabhodhi rekudhinda, rinowanzo kugoverwa nekuparadzira kana simbi skrini yekudhinda nzira. Mushure mekuisa zvikamu, zviise muchoto kana reflow furnace yekupisa nekuomesa. Musiyano uripo pakati payo uye solder paste ndeyekuti inoporeswa mushure mekupisa, kutonhora kwayo kunosvika 150 ° C, uye haizonyungudika mushure mekudziyisazve, ndiko kuti, kupisa kwekuomesa kwechigamba hakuchinjiki. Iko kushandiswa kweSMT adhesive kuchasiyana nekuda kwemamiriro ekurapa ekupisa, chinhu chakabatana, midziyo inoshandiswa, uye nharaunda yekushanda. Iyo yekunamatira inofanirwa kusarudzwa zvinoenderana neyakadhindwa yedunhu bhodhi musangano (PCBA, PCA) maitiro.

Hunhu, mashandisirwo uye tarisiro yeSMT chigamba chinonamira

SMT dzvuku glue imhando yepolymer mukomboni, iwo makuru maficha ndiwo akadzika zvinhu (kureva, iyo huru yakakwira molecular material), filler, kurapa mumiririri, zvimwe zvinowedzera uye zvichingodaro. SMT red glue ine viscosity fluidity, tembiricha maitiro, wetting maitiro uye zvichingodaro. Zvinoenderana nehunhu uhu hwehudyu dzvuku, mukugadzirwa, chinangwa chekushandisa dzvuku glue ndechekuita kuti zvikamu zvinyatsonamira kumusoro kwePCB kudzivirira kuti irege kudonha. Naizvozvo, chigamba chinonamirwa ndechekushandiswa kwakachena kwezvisingakoshese zvigadzirwa, uye iko zvino nekuenderera mberi kwekuvandudzwa kwePCA dhizaini uye maitiro, kuburikidza negomba reflow uye kaviri-sided reflow welding zvave kuitika, uye PCA yekumisikidza maitiro uchishandisa chigamba chekunamira chiri kuratidza maitiro ezvishoma uye zvishoma.

Chinangwa chekushandisa SMT adhesive

① Dzivirira zvinhu kubva pakudonha mu wave soldering (wave soldering process). Paunenge uchishandisa wave soldering, zvikamu zvinogadziriswa pabhodhi rakadhindwa kudzivirira kuti zvikamu zvirege kudonha kana bhodhi rakadhindwa richipfuura nepakati pe solder groove.

② Dzivirira rumwe rutivi rwezvikamu kubva pakudonha mu reflow welding (double-sided reflow welding process). Muchikamu cheviri-side reflow welding process, kuitira kudzivirira michina mikuru padivi rakatengeswa kuti isadonha nekuda kwekunyungudika kwekupisa kweiyo solder, SMT chigamba glue chinofanira kuitwa.

③ Dzivirira kutamiswa uye kumira kwezvikamu (reflow welding process, pre-coating process). Inoshandiswa mune reflow welding maitiro uye pre-coating maitiro ekudzivirira kutamiswa uye riser panguva yekukwira.

④ Maka (wave soldering, reflow welding, pre-coating). Mukuwedzera, kana mabhodhi akadhindwa uye zvikamu zvakashandurwa mumabheti, chigamba chekunamatira chinoshandiswa pakumaka.

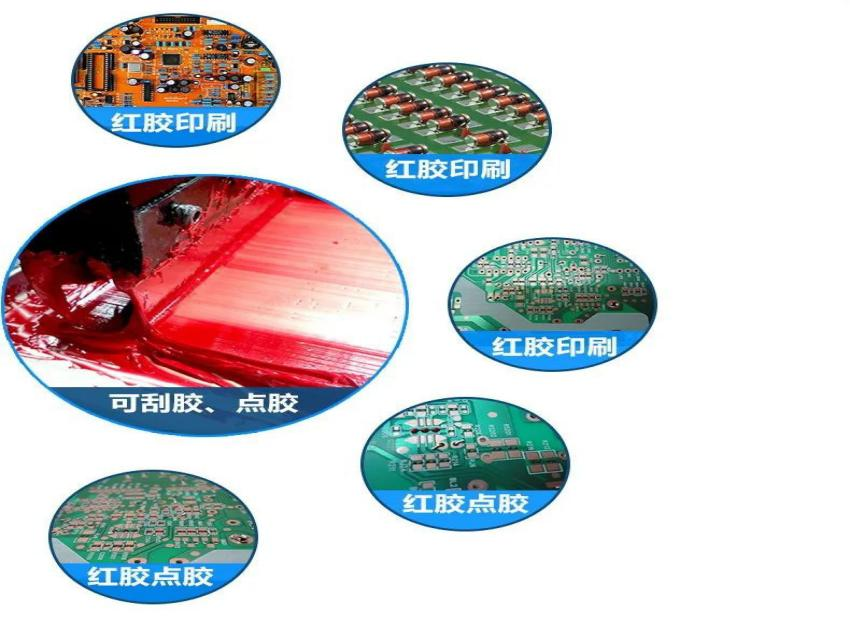

SMT adhesive inokamurwa zvinoenderana nemaitiro ekushandisa

a) Rudzi rwekukwenya: saizi inoitwa kuburikidza nekudhinda uye kukwenya maitiro esimbi mesh. Iyi nzira ndiyo inonyanya kushandiswa uye inogona kushandiswa zvakananga pane solder paste press. Makomba esimbi mesh anofanirwa kutariswa zvichienderana nerudzi rwezvikamu, kuita kwe substrate, ukobvu uye saizi uye chimiro chemakomba. Zvakanakira zvaro kukurumidza kukurumidza, kushanda kwakanyanya uye mutengo wakaderera.

b) Rudzi rwekugovera: Iyo glue inoshandiswa pane yakadhindwa redunhu bhodhi nekuparadzira michina. Special dispensing equipment inodiwa, uye mutengo wacho wakakwira. Midziyo yekuparadzira iko kushandiswa kwemhepo yakamanikidzwa, iyo tsvuku glue kuburikidza neakakosha musoro wekugovera kune substrate, saizi yeglue point, yakawanda sei, nenguva, yekumanikidza chubhu dhayamita uye mamwe ma paramita ekudzora, muchina wekuparadzira une basa rinoshanduka. Kune zvikamu zvakasiyana, tinogona kushandisa misoro yakasiyana yekuparadzira, kuisa maparamita ekuchinja, iwe unogona zvakare kushandura chimiro uye huwandu hweglue point, kuitira kuti uwane mhedzisiro, zvakanakira zviri nyore, zvinochinjika uye zvakagadzikana. Kukanganisa kuri nyore kuve newaya kudhirowa uye mabhuru. Tinogona kugadzirisa ma parameter ekushanda, kumhanya, nguva, mhepo yekumanikidza, uye tembiricha kuti tideredze zvikanganiso izvi.

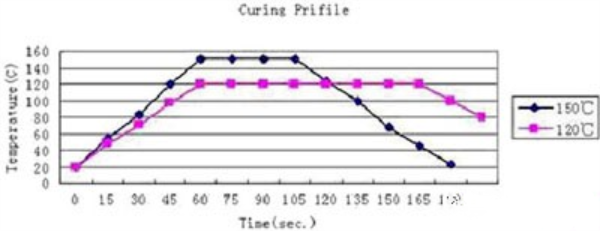

SMT chigamba chinonamira chakajairwa kurapa mamiriro

| Kurapa tembiricha | Nguva yekuzorora |

| 100 ℃ | 5 maminitsi |

| 120 ℃ | 150 seconds |

| 150 ℃ | 60 seconds |

Cherechedza:

1, iyo yakakwirira tembiricha yekurapa uye kurebesa nguva yekurapa, ndiko kusimba kwesimba rekubatanidza.

2, nekuti tembiricha yekunamira kwechigamba ichachinja nehukuru hwezvikamu zve substrate uye chinzvimbo chekumisikidza, tinokurudzira kuti tiwane yakanyanya kuomarara mamiriro.

Kuchengetedzwa kweSMT zvigamba

Inogona kuchengetwa kwemazuva manomwe patembiricha yekamuri, kweanopfuura mwedzi mitanhatu isingasviki 5 ° C, uye kwemazuva anopfuura 30 pa5 ~ 25 ° C.

SMT adhesive manejimendi

Nekuti SMT chigamba dzvuku guruu inokanganiswa netembiricha ine viscosity yayo, fluidity, kunyorova uye humwe hunhu, saka SMT chigamba tsvuku glue inofanira kunge iine mamwe mamiriro ekushandiswa uye yakajairwa manejimendi.

1) Gluu tsvuku inofanira kuva nenhamba chaiyo yekuyerera, zvichienderana nehuwandu hwekudya, zuva, rudzi kune nhamba.

2) Gluu tsvuku inofanira kuchengetwa mufiriji pa2 ~ 8 ° C kudzivirira maitiro kubva pakukanganiswa nekuda kwekushanduka kwekushisa.

3) Iyo tsvuku tsvuku inodiwa kuti idziyirwe pakupisa kwemaawa kwemaawa mana, muhurongwa hwekutanga-mu-kutanga-kunze kushandiswa.

4) Nokuda kwekushanda kwekuparadzira, tsvuku tsvuku yepombi inofanira kusvibiswa, uye tsvuku tsvuku isina kushandiswa inofanira kudzoserwa mufiriji yekuchengetedza, uye glue yekare uye itsva itsva haigoni kusanganiswa.

5) Kuzadza nenzira kwayo fomu rekodhi rekodhi rekodhi, munhu anodzosa tembiricha uye nguva yekudzoka tembiricha, mushandisi anofanirwa kusimbisa kupedzwa kwekushisa kwekudzoka usati washandisa. Kazhinji, glue dzvuku haigoni kushandiswa kunze kwezuva.

Maitiro maitiro eSMT chigamba adhesive

Simba rekubatanidza: SMT yakanamatira inofanira kuva nesimba rakasimba rekubatanidza, mushure mekuomeswa, kunyange pakunyunguduka kwekushisa kwe solder haina peel.

Dot coating: Parizvino, nzira yekugovera yemapuranga akadhindwa anonyanya kupfekedzwa doti, saka glue rinodiwa kuve neanotevera zvivakwa:

① Chinja kune akasiyana maitiro ekukwira

Zviri nyore kuseta kupihwa kwechimwe nechimwe chikamu

③ Rakareruka kugadzirisa kutsiva chikamu chemhando dzakasiyana

④ Yakagadzikana dot coating huwandu

Adap kumuchina wekumhanya-mhanya: chigamba chekunamira iko zvino chashandiswa chinofanira kusangana nekumhanya-mhanya kwenzvimbo yekuputira uye yakakwirira-yekumhanyisa chigamba muchina, kunyanya, ndiko kuti, yakakwirira-yekumhanyisa nzvimbo yekuputira isina waya yekudhirowa, uye ndiko kuti, kukwirisa-kumhanya, kudhindwa bhodhi munzira yekutapurirana, inonamira kuti ive nechokwadi chekuti zvikamu hazvifambi.

Kudhirowa kwewaya, kudonha: kana chigamba cheglue chanamatira padhi, zvikamu hazvigone kuwana kubatana kwemagetsi nebhodhi rakadhindwa, saka chigamba cheglue hachifanirwe kunge chisina kudhirowa waya panguva yekupfeka, hapana kudonha mushure mekupfeka, kuti usasvibisa padhi.

Kurapa kwakadzika-tembiricha: Kana uchirapa, iyo inodzivirira kupisa-inodzivirira plug-muzvikamu zvakasungwa newave crest welding inofanirawo kupfuura nepakati reflow welding vira, saka mamiriro ekuoma anofanira kusangana neakadzika tembiricha uye nguva pfupi.

Kuzvigadzirisa: Mune reflow welding uye pre-coating process, chigamba glue chinoporeswa uye chinogadziriswa solder isati yanyunguduka, saka inodzivirira chikamu kuti chisanyura mune solder uye kuzvigadzirisa. Mukupindura kune izvi, vagadziri vakagadzira chigamba chekuzvigadzirisa.

SMT inonamatira zvakajairika matambudziko, kukanganisa uye kuongorora

underthrust

Iyo 0603 simba inodiwa ye 0603 capacitor ndeye 1.0KG, kuramba iri 1.5KG, iyo 0805 capacitor simba ndeye 1.5KG, kuramba ndeye 2.0KG, iyo isingakwanise kusvika pamusoro apa, zvichiratidza kuti simba harina kukwana.

Kazhinji zvinokonzerwa nezvikonzero zvinotevera:

1, kuwanda kweglue hakuna kukwana.

2, iyo colloid haina kupora 100%.

3, PCB board kana zvikamu zvakasvibiswa.

4, iyo colloid pachayo haina brittle, haina simba.

Thixotropic kusagadzikana

Iyo 30ml sirinji glue inoda kurohwa makumi ezviuru zvenguva nekumanikidzwa kwemhepo kuti ishandiswe kumusoro, saka chigamba glue pachacho chinodiwa kuti ive yakanakisa thixotropy, zvikasadaro zvinokonzeresa kusagadzikana kweglue point, yakawandisa glue, izvo zvinozotungamira mukusakwana simba, zvichiita kuti zvikamu zviwire pasi panguva yekuzunguza kwemafungu, pane zvinopesana, huwandu hweglue kune zvidiki zvakawandisa, kudzivirira kunamatira kwemagetsi, kunyanya kunamatira.

Guruu isina kukwana kana nzvimbo inodonha

Zvikonzero uye Matanho:

1, bhodhi rokudhinda harina kucheneswa nguva dzose, rinofanira kucheneswa ne ethanol maawa masere oga oga.

2, iyo colloid ine tsvina.

3, kuvhurwa kwebhodhi mesh kusinganzwisisike kudiki zvakanyanya kana kudzvanywa kwekuparadzira kudiki, dhizaini yeglue isina kukwana.

4, kune mabhuru mune colloid.

5. Kana musoro wekugovera wakavharwa, muromo wekugovera unofanirwa kucheneswa nekukurumidza.

6, tembiricha yekupisa yemusoro wekugovera haina kukwana, tembiricha yemusoro wekugovera inofanira kuiswa pa38 ℃.

waya-kudhirowa

Iyo inonzi dhizaini yekudhirowa ndiyo chiitiko chekuti chigamba glue hachina kuputswa kana ichiparadzira, uye chigamba glue chinobatanidzwa nenzira ine filamentous munzira yemusoro unoparadzira. Kune mamwe mawaya, uye chigamba glue chakavharwa pane yakadhindwa padhi, izvo zvinokonzeresa kushomeka. Kunyanya kana saizi yakakura, chiitiko ichi chinowanzoitika kana poindi yakaputira muromo. Kudhirowa kwechigamba glue kunonyanya kukanganiswa neiyo yekudhirowa pfuma yechikamu chayo chikuru resin uye kumisikidzwa kweiyo point coating mamiriro.

1, wedzera kuparadzira sitiroko, kuderedza kumhanya kwekufamba, asi kunoderedza kurova kwako kwekugadzira.

2, iyo yakanyanya kuderera viscosity, yakakwirira thixotropy yezvinhu, iyo diki tsika yekudhirowa, saka edza kusarudza chigamba chakanamira chakadaro.

3, tembiricha ye thermostat yakakwira zvishoma, inomanikidzwa kuchinjika kune yakaderera viscosity, yakakwira thixotropic chigamba glue, wobva wafunga zvakare nguva yekuchengetedza yechigamba glue uye kudzvanywa kwemusoro unoparadzira.

caving

Iyo fluidity yechigamba ichakonzera kudonha. Dambudziko rinowanzoitika rekudonha nderekuti kuisa nguva refu mushure mekuputira nzvimbo kunokonzeresa kudonha. Kana iyo chigamba glue ichitambanudzirwa kune padhi yeakadhindwa redunhu bhodhi, inokonzeresa kusaina welding. Uye kudonha kwechigamba chekunamira kune izvo zvikamu zvine mapini akareba, hazvibatike muviri mukuru wechikamu, izvo zvinokonzeresa kusakwana kwekunamatira, saka kuwanda kwekudonha kwechigamba chekunamira icho chiri nyore kudonha chakaoma kufanotaura, saka yekutanga kugadzika kweiyo dot coating uwandu kwakaomawo. Tichifunga nezveizvi, isu tinofanirwa kusarudza izvo zvisiri nyore kudonha, ndiko kuti, chigamba chakanyanya kukwirira mukuzunungusa mhinduro. Nekuputsika kunokonzerwa nekuisa yakarebesa mushure mekupfekedzwa kwemavara, tinogona kushandisa nguva pfupi mushure mekupotera kwenzvimbo kupedzisa chigamba glue, kurapa kudzivirira.

Component offset

Component offset chinhu chisingadiwe chiri nyore kuitika mumichina yekumhanya-mhanya yeSMT, uye zvikonzero zvikuru ndezvi:

1, ndiyo yakadhindwa bhodhi yepamusoro-yekukurumidza kufamba kweiyo XY kutungamira kunokonzerwa neiyo offset, chigamba chinonamira chekuvhara nzvimbo yezvikamu zvidiki zvinotarisana nechiitiko ichi, chikonzero ndechekuti kunamatira hakuna kukonzerwa.

2, chiyero cheglue pasi pezvikamu hazvienderani (zvakadai se: mapeji maviri eglue pasi pe IC, imwe glue point yakakura uye imwe glue point iduku), simba reglue harina kuenzana kana rinopisa uye rinoporeswa, uye kuguma ne glue shoma zviri nyore kugadzirisa.

Over wave soldering kubva zvikamu

Zvikonzero zvakaoma:

1. Simba rekunamatira rechigamba harina kukwana.

2. Yakave yakakanganiswa isati yave soldering.

3. Pane zvimwe zvakasara pane zvimwe zvikamu.

4, iyo colloid haimirire kune yakanyanya kupisa tembiricha

Patch glue musanganiswa

Vagadziri vakasiyana-siyana vechigamba glue mumakemikari ane mutsauko mukuru, kushandiswa kwakavhengana kuri nyore kubudisa yakawanda yakaipa: 1, kuporesa kuoma; 2, iyo yekunamatira relay haina kukwana; 3, over wave soldering off serious.

Mhinduro ndeyokuti: nyatsochenesa mesh board, scraper, dispensing uye zvimwe zvikamu zviri nyore kukonzera kusanganiswa, uye kudzivisa kusanganisa mhando dzakasiyana dzechigamba glue.