Yakadzama PCBA yekugadzira maitiro (kusanganisira iyo yese maitiro eDIP), huya uone!

"Wave Soldering Process"

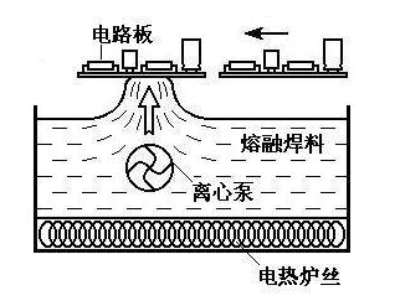

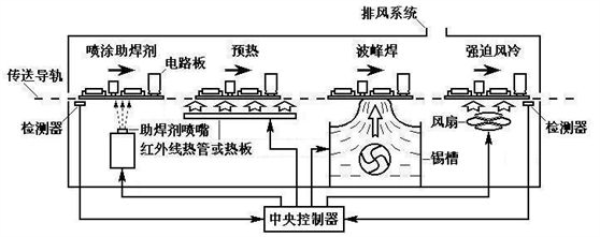

Wave soldering inowanzoita welding process yeplug-in zvishandiso. Iwo maitirwo ekuti solder yemvura yakanyungudutswa, nerubatsiro rwepombi, inoumba chimiro chakati che solder wave pamusoro pemvura yetangi rekutengesa, uye PCB yechikamu chakaiswa ichipfuura nepamusoro peiyo solder wave peak pane chaiyo Angle uye nekumwe kunyudzwa kudzika pacheni yekutapurirana kuti uwane solder joint welding, sezvakaratidzwa mumufananidzo uri pazasi.

The general process flow flowing ndozvinoita: kupinza mudziyo --PCB loading -- wave soldering --PCB unloading --DIP pin trimming -- kuchenesa, sezvinoratidzwa pamufananidzo uri pazasi.

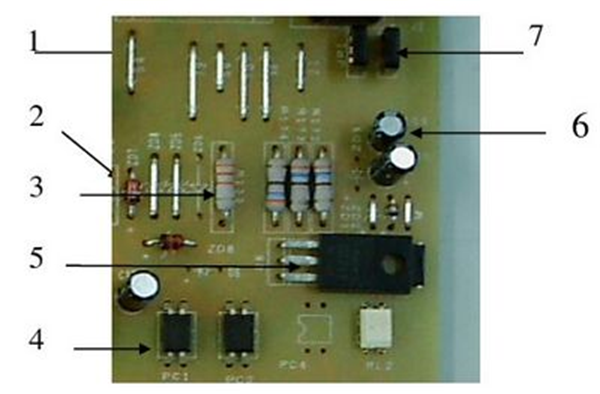

1.THC yekuisa tekinoroji

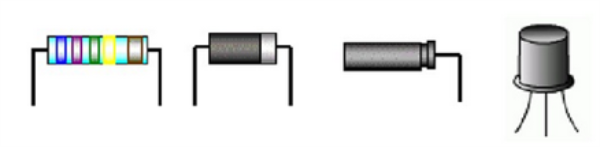

1. Chikamu chepini kuumba

DIP midziyo inoda kuumbwa isati yaiswa

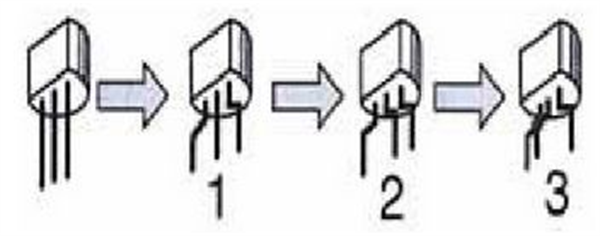

(1) Kuumbwa kwechikamu chakagadzirwa nemaoko: Pini yakabhenda inogona kuumbwa nediki kana screwdriver diki, sezvakaratidzwa pamufananidzo uri pazasi.

(2) Kugadziriswa kwemuchina wezvikamu zvekuumba: kuumbwa kwemuchina wezvikamu kunopedzwa nemuchina wakakosha wekuumba, musimboti wayo wekushanda ndewekuti feeder inoshandisa vibration feeding kudyisa zvinhu, (senge plug-in transistor) ine divider kutsvaga transistor, nhanho yekutanga kukotamisa mapini pamativi ese ekuruboshwe nekurudyi mativi; Nhanho yechipiri ndeyekukotamisa pini yepakati kumashure kana kumberi kuti iite. Sezvinoratidzwa pamufananidzo unotevera.

2. Isa zvikamu

Kuburikidza negomba rekupinza tekinoroji yakakamurwa kuita manyore yekuisa uye otomatiki machira ekuisa midziyo

(1) Kuisa nemaoko uye welding kunofanirwa kutanga kuisa izvo zvinoda kugadziriswa nemuchina, senge rekutonhodza, bracket, clip, nezvimwe, zvemagetsi mudziyo, uye wozoisa izvo zvinoda kuiswa weld nekugadziriswa. Usabata chikamu mapini uye foil yemhangura pane yekudhinda ndiro zvakananga paunenge uchiisa.

(2) Mechanical otomatiki plug-in (inonzi AI) ndiyo yepamusoro-soro yekugadzira tekinoroji mukuiswa kwezvigadzirwa zvemagetsi zvemazuva ano. Kuiswa kwe otomatiki mechanical midziyo inofanira kutanga yaisa izvo zvikamu zvine hurefu hwakaderera, wozoisa izvo zvikamu zvine hurefu hwepamusoro. Zvinhu zvakakosha zvakakosha zvinofanirwa kuiswa mukuiswa kwekupedzisira. Kuiswa kwekupisa kupisa rack, bracket, clip, nezvimwe zvinofanirwa kunge zviri padyo neiyo welding process. Kutevedzana kwegungano kwezvikamu zvePCB kunoratidzwa mumufananidzo unotevera.

3. Wave soldering

(1) Kushanda musimboti wewave soldering

Wave soldering imhando yetekinoroji inoumba chimiro chakati che solder wave pamusoro peyakanyungudutswa yemvura solder nenzira yekupomba kudzvanywa, uye inogadzira nzvimbo inotengeswa munzvimbo yepini welding kana chikamu chegungano chinopinzwa nechikamu chinopfuura nepamasolder wave paAngle yakatarwa. Icho chikamu chinotanga kupiswa mumushini wewelding preheating zone panguva yekufambiswa neketani conveyor (chikamu chinopisa uye tembiricha ichawanikwa ichiri kudzorwa neyakafanotemerwa tembiricha curve). Mune welding chaiyo, zvinowanzodiwa kudzora tembiricha yekupisa yechikamu chepamusoro, saka michina mizhinji yakawedzera inowirirana tembiricha yekuona michina (senge infrared detectors). Mushure mekutanga kupisa, gungano rinopinda mugomba rekutungamirira kune welding. Iyo tin tangi ine yakanyungudutswa yemvura solder, uye muromo uri pazasi pe tangi resimbi inopfapfaidza yakamisikidzwa yakaumbwa wave crest yeyakanyungudutswa solder, kuitira kuti kana welding pamusoro pechikamu ichipfuura nepasaisai, inopiswa ne solder wave, uye solder wave inonyorovesawo nzvimbo yewelding uye inowedzera kuzadza, pakupedzisira ichiwana iyo welding process. Nheyo yayo yekushanda inoratidzwa mumufananidzo uri pasi apa.

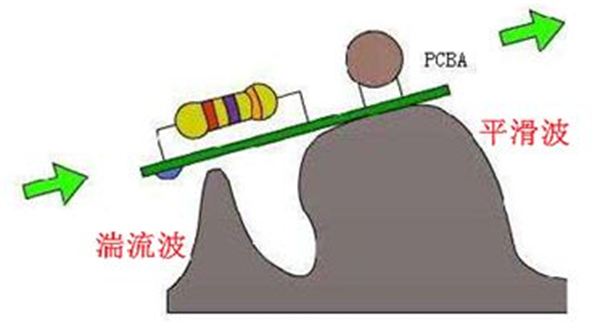

Wave soldering inoshandisa convection heat transfer musimboti kupisa nzvimbo yewelding. Iyo yakanyungudutswa solder wave inoshanda senge sosi yekupisa, kune rumwe rutivi ichiyerera kugeza pini welding nzvimbo, kune rumwe rutivi inotambawo kupisa conduction basa, uye pini welding nzvimbo inopisa pasi pechiito ichi. Kuti uone kuti nzvimbo yekupisa inopisa, solder wave inowanzova nehumwe hupamhi, kuitira kuti kana welding pamusoro pechikamu ichipfuura nepakati pemafungu, pane zvakakwana kupisa, kunyorova, nezvimwewo. Muchinyakare wave soldering, single wave inowanzoshandiswa, uye wave yakati sandarara. Nekushandiswa kwe lead solder, ikozvino inogamuchirwa nenzira yeviri wave. Sezvinoratidzwa pamufananidzo unotevera.

Pini yechikamu inopa nzira yekuti solder inyudze mukati mesimbi kuburikidza negomba munzvimbo yakasimba. Kana pini yabata solder wave, liquid solder inokwira nepini neburi remadziro nenzira yekumanikidzana kwepamusoro. Iyo capillary chiito chesimbi kuburikidza nemakomba inovandudza solder kukwira. Mushure mekunge solder yasvika paPcB pad, inopararira pasi pekuita kwekunetseka kwepamusoro pedhi. Solder inosimuka inodhonza gasi nemhepo kubva mugomba, nokudaro ichizadza neburi-paburi uye kugadzira iyo solder joint mushure mekutonhodzwa.

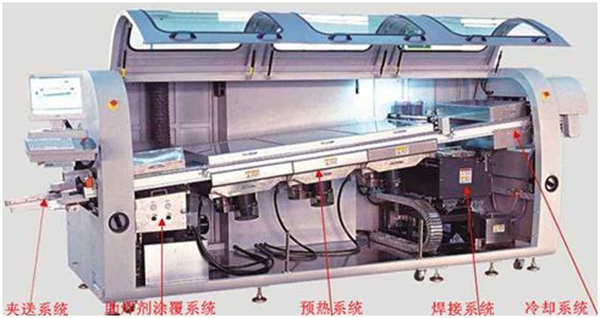

(2) Izvo zvikamu zvikuru zve wave welding muchina

Muchina wewelding wemuchina unonyanya kuumbwa nebhandi rekutakura, hita, tangi rerata, pombi, uye furo rinopupuma (kana kupfapfaidza) mudziyo. Iyo inonyanya kukamurwa kuita flux yekuwedzera zone, preheating zone, welding zone uye inotonhorera zone, sezvinoratidzwa mumufananidzo unotevera.

3. Misiyano mikuru pakati pe wave soldering uye reflow welding

Musiyano mukuru pakati pe wave soldering uye reflow welding ndeyekuti kupisa sosi uye solder yekugovera nzira muwelding zvakasiyana. Mune wave soldering, solder inofanopisa uye yakanyungudutswa mutangi, uye solder wave inogadzirwa nepombi inoita mbiri mbiri yekupisa sosi uye solder kupihwa. Iyo yakanyungudutswa solder wave inopisa kuburikidza nemaburi, mapadhi, uye mapini echikamu chePCB, ichipawo solder inodiwa kugadzira majoini ekutengesa. Mukugadzirisa reflow soldering, solder (solder paste) inotanga kugoverwa kune welding nzvimbo yePCB, uye basa remhepo inopisa panguva yekuyerera ndeyekunyungudutsa zvakare solder.

(1) 3 Nhanganyaya yekusarudza wave soldering process

Wave soldering midziyo yakagadzirwa kweanopfuura makore makumi mashanu, uye ine zvakanakira kugadzirwa kwepamusoro uye goho rakakura mukugadzira kuburikidza negomba zvinoriumba uye edunhu mabhodhi, saka yaimbove inonyanya kukosha welding midziyo mune otomatiki misa kugadzirwa kwemagetsi zvigadzirwa. Nekudaro, pane zvimwe zvipimo mukushandiswa kwayo: (1) iyo welding paramita dzakasiyana.

Majoini akasiyana ekutengesa pabhodhi redunhu rimwe chete angada maparamendi akasiyana-siyana nekuda kwehunhu hwawo hwakasiyana (sekupisa huwandu, kupatsanurwa kwepini, tin kupinza zvinodiwa, nezvimwewo). Zvisinei, hunhu wave soldering ndiko kupedza nomoto ose solder mapfundo ose redunhu bhodhi pasi zvakafanana yakatarwa parameters, saka siyana solder majoini vanofanira "kugarisana" mumwe, izvo zvinoita kuti masaisai soldering zvakaoma kuzadzisa zvizere nomoto zvinodiwa zvemhando yepamusoro redunhu mapuranga;

(2) Mari yekushandisa yakakwirira.

Mukushandiswa kunoshanda kwechinyakare wave soldering, iyo ndiro yese kupfapfaidza ye flux uye chizvarwa chetin slag zvinounza yakakwira mitengo yekushandisa. Kunyanya kana mutobvu-isina welding, nekuti mutengo we lead-isina solder unopfuura ka3 kupfuura iyo lead solder, kuwedzera kwekushandisa mari kunokonzerwa netin slag kunoshamisa zvikuru. Mukuwedzera, iyo inotungamira-isina solder inoramba ichinyungudutsa mhangura padhi, uye kuumbwa kwe solder mu tin cylinder kuchachinja nekufamba kwenguva, izvo zvinoda nguva dzose kuwedzera kweti yakachena uye sirivha inodhura kugadzirisa;

(3) Kugadzirisa uye kugadzirisa dambudziko.

Iyo yakasara inoyerera mukugadzirwa icharamba iri muhurongwa hwekutumira wave soldering, uye tin slag inogadzirwa inoda kubviswa nguva dzose, iyo inounza zvakanyanya kuoma kwemidziyo kugadzirisa uye kugadzirisa basa kumushandisi; Nekuda kwezvikonzero zvakadaro, sarudzo yekunyungudutsa yakavepo.

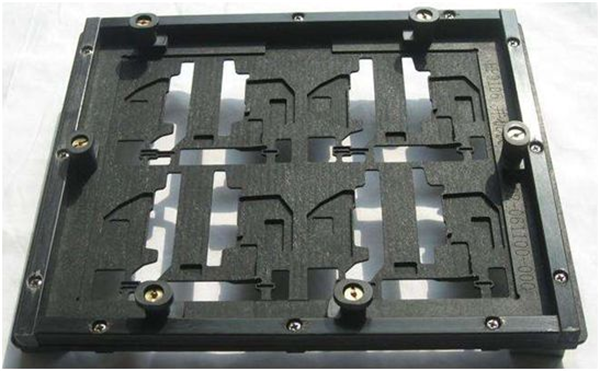

Iyo inonzi PCBA selective wave soldering ichiri kushandisa iyo yepakutanga tin choto, asi mutsauko ndewekuti bhodhi rinoda kuiswa mutakuri wevira, izvo zvatinowanzotaura pamusoro pechoto chemoto, sezvakaratidzwa mumufananidzo uri pasi apa.

Izvo zvikamu zvinoda wave soldering zvinozoiswa pachena kune tini, uye zvimwe zvikamu zvinodzivirirwa nekuvharirwa kwemotokari, sezvaratidzwa pazasi. Izvi zvakangofanana nekuisa bhuya rehupenyu mudziva rekutuhwina, nzvimbo yakafukidzwa nebhuya rehupenyu haiwane mvura, uye yakatsiviwa nechitofu cherata, nzvimbo yakavharwa nemotokari haizowani marata, uye hapazovi nedambudziko rekunyungudusazve marata kana zvidimbu zvinodonha.

"Kuburikidza negomba reflow Welding process"

Kuburikidza ne-hole reflow welding inzira yekudzorerazve yekuisa zvinhu, iyo inonyanya kushandiswa mukugadzira ma plates emusangano wepamusoro ane maplug-ins mashoma. Nheyo yetekinoroji ndiyo nzira yekushandisa ye solder paste.

1. Kusuma nzira

Zvinoenderana nekushandisa nzira yekuisa solder paste, kuburikidza negomba reflow welding inogona kukamurwa kuita marudzi matatu: pombi kudhinda kuburikidza negomba reflow welding process, solder paste kudhinda kuburikidza negomba reflow welding process uye yakaumbwa tin sheet kuburikidza negomba reflow welding process.

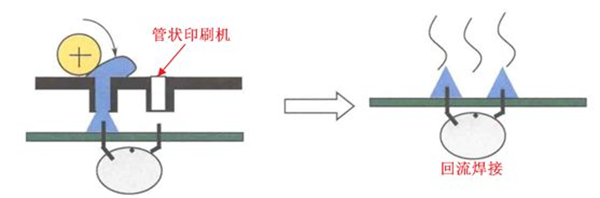

1) Tubular kudhinda kuburikidza negomba reflow welding process

Tubular kudhinda kuburikidza negomba reflow welding process ndiyo yekutanga kushandiswa kweburi reflow welding process, iyo inonyanya kushandiswa mukugadzirwa kweruvara TV tuner. Nheyo yemaitiro ndeye solder paste tubular press, maitiro anoratidzwa mumufananidzo uri pasi apa.

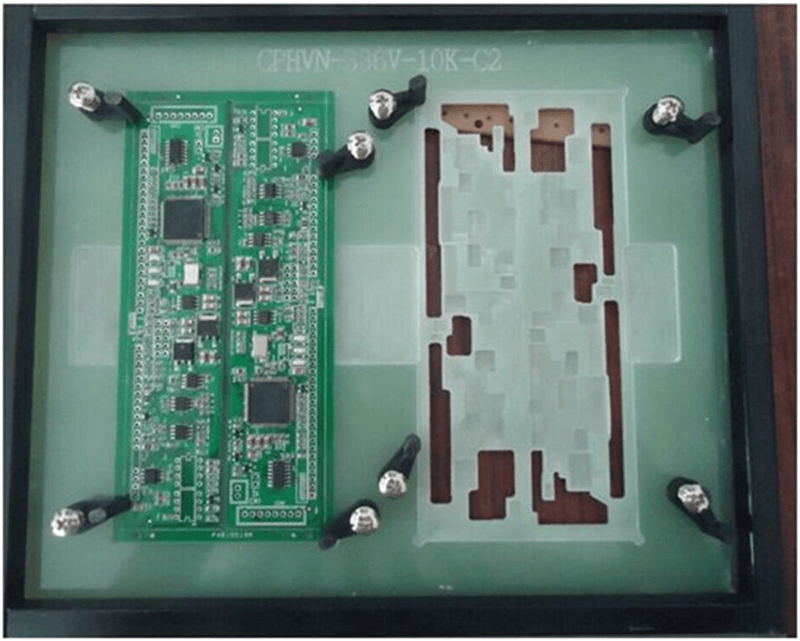

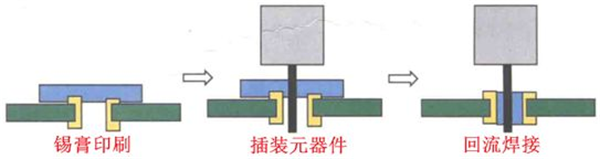

2) Solder paste kudhinda kuburikidza negomba reflow welding process

Solder paste kudhinda kuburikidza negomba reflow welding process parizvino ndiyo inonyanya kushandiswa kuburikidza negomba reflow welding process, inonyanya kushandiswa kune yakasanganiswa PCBA ine nhamba diki yeplug-ins, maitiro acho anonyatsoenderana neyakajairwa reflow welding process, hapana yakakosha dhizaini inodiwa, chinodiwa chete ndechekuti iyo welded plug-in zvikamu zvinofanirwa kuve zvakakodzerwa kuburikidza negomba reflow rinoratidzwa.

3) Kuumba tin sheet kuburikidza negomba reflow welding process

Yakaumbwa tin sheet kuburikidza negomba reflow welding process inonyanya kushandiswa kune akawanda-pini majoini, solder haisi solder paste asi yakaumbwa tani pepa, kazhinji nemugadziri wekubatanidza akawedzera zvakananga, gungano rinogona kupisa chete.

Kuburikidza negomba reflow design zvinodiwa

1.PCB kugadzira zvinodiwa

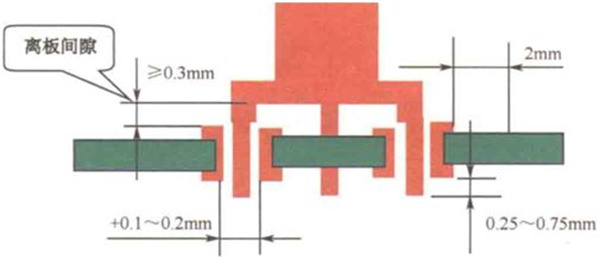

(1) Inokodzera PCB ukobvu isingasviki kana yakaenzana ne1.6mm bhodhi.

(2) Hupamhi hudiki hwepadhi ndeye 0.25mm, uye yakanyungudutswa solder paste "inodhonzwa" kamwe chete, uye bead yerata haina kuumbwa.

(3) Chikamu che-off-board gap (Kumira-kure) chinofanira kunge chakakura kupfuura 0.3mm

(4) Hurefu hwakakodzera hwemutungamiri unonamatira kunze kwepadhi ndeye 0.25 ~ 0.75mm.

(5) Iyo diki nhambwe pakati pezvakanaka spacing zvikamu zvakaita se0603 uye padhi i2mm.

(6) Iyo yakanyanya kuvhura yesimbi mesh inogona kuwedzerwa ne 1.5mm.

(7) The aperture ndiyo dhayamita inotungamira plus 0.1 ~ 0.2mm. Sezvinoratidzwa pamufananidzo unotevera.

"Simbi mesh kuvhura hwindo zvinodiwa"

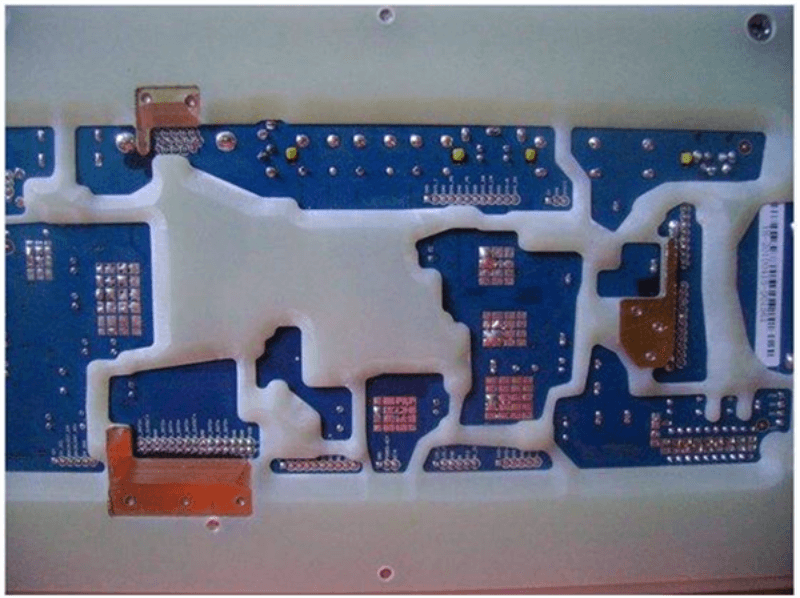

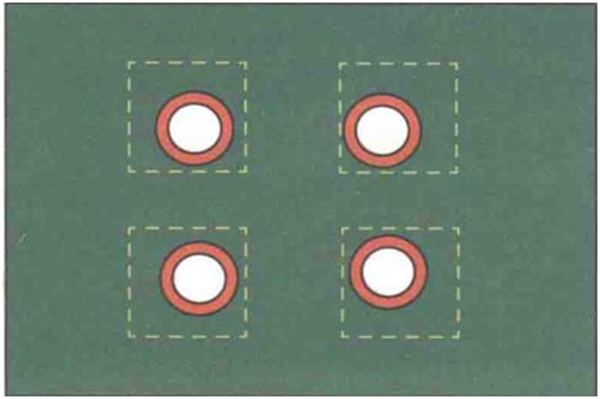

Kazhinji, kuti uwane 50% kuzadza gomba, hwindo resimbi mesh rinofanirwa kuwedzerwa, huwandu hwekuwedzera hwekunze hunofanirwa kutariswa zvinoenderana nePCB ukobvu, ukobvu hwesimbi mesh, mukaha pakati pegomba uye lead nezvimwe zvinhu.

Kazhinji, chero bedzi kuwedzera kusingapfuuri 2mm, iyo solder paste inodhonzwa kumashure uye izere mugomba. Izvo zvinofanirwa kucherechedzwa kuti yekuwedzera yekunze haigone kudzvanywa nechikamu pasuru, kana inofanira kudzivirira pasuru muviri wechikamu, uye kuumba bhidhi retin kune rumwe rutivi, sezvinoratidzwa mumufananidzo unotevera.

"Sumo kune yakajairwa Gungano Maitiro ePCBA"

1) Single-side mounting

Kuyerera kwemaitiro kunoratidzwa mumufananidzo uri pasi apa

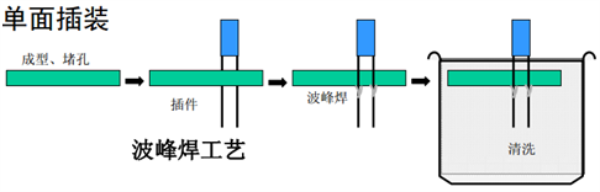

2) Single side kuiswa

Kuyerera kwemaitiro kunoratidzwa muMufananidzo 5 pazasi

Iko kuumbwa kwepini yemudziyo mune wave soldering ndeimwe yeasina kunyatsoshanda zvikamu zvekugadzira, izvo zvinoenderana zvinounza njodzi yekukuvara kwemagetsi uye kuwedzera nguva yekutumira, uye zvakare inowedzera mukana wekukanganisa.

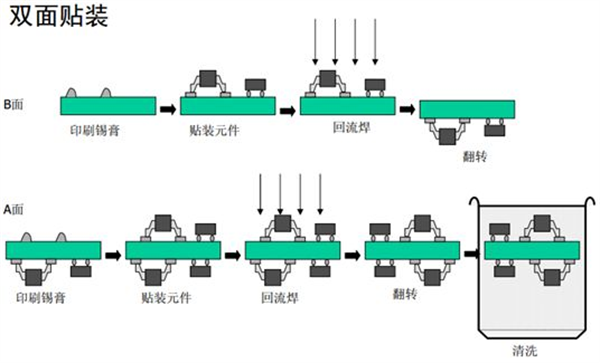

3) Kuiswa kwakapetwa kaviri

Kuyerera kwemaitiro kunoratidzwa mumufananidzo uri pasi apa

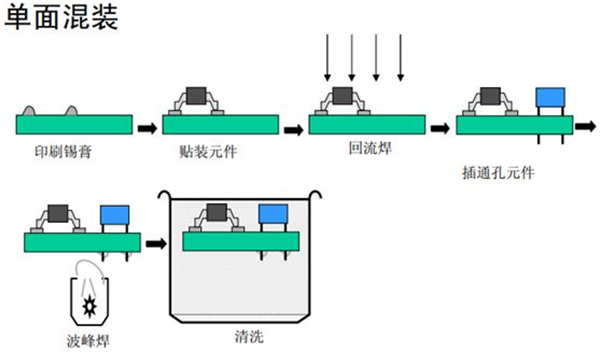

4) Rutivi rumwe rwakasanganiswa

Kuyerera kwemaitiro kunoratidzwa mumufananidzo uri pasi apa

Kana paine mashoma kuburikidza-mugomba zvikamu, reflow welding uye manual welding inogona kushandiswa.

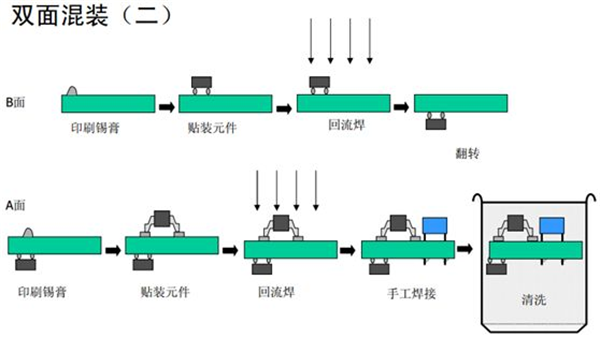

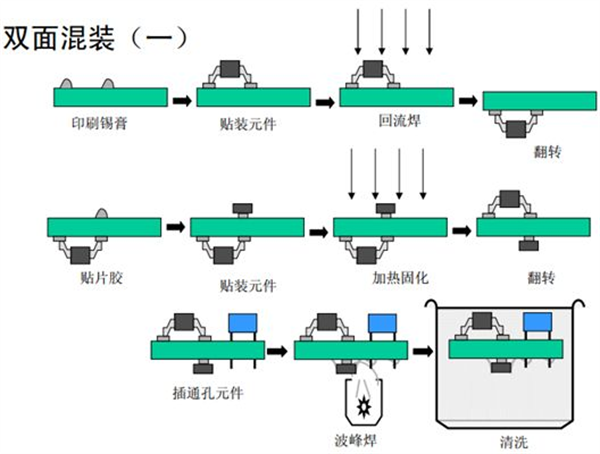

5) Kusanganiswa kwemativi maviri

Kuyerera kwemaitiro kunoratidzwa mumufananidzo uri pasi apa

Kana paine mamwe madhivhari maviri-mativi eSMD zvishandiso uye mashoma eTHT zvikamu, iyo plug-in zvishandiso zvinogona kuyerera zvakare kana manyore welding. Iyo process flow chart inoratidzwa pazasi.